Home » Products » Sample Preparation » VITRIOX® Electric Fusion Systems

VITRIOX® Electric Fusion Systems

The VITRIOX® Electric Fusion Systems is a state-of-the-art electric fusion system for efficient and precise XRF and ICP sample preparation.

Product Overview

VITRIOX® Electric fusion systems, offered by SciMed through Fluxana, are designed to offer the ultimate in precision sample preparation for XRF fused bead analysis.

These systems offer “cold to cold”, gas-free fusion operation with multiple safety features to protect both the user and the equipment.

They are ideal for a wide range of applications, including geological samples, cement production, mining, and metals processing, ensuring uniform sample homogenization and high-volume sample handling.

With multiple options for different sample throughput requirements and optional ICP preparation module the VITRIOX® Electric range offers a complete solution for all sample fusion needs.

Features & Benefits

Bottom-loading furnace

Closed, bottom-loading chamber gives best temperature control

Intuitive touch screen

Simple operation and monitoring of fusion progress

High throughput option

VITRIOX® 4+ chamber capacity fuses 4 samples simultaneously

Key applications

- Automated “cold to cold” fusion: fully automated loading, fusion, casting and cooling with storage of up to 20 different fusion programs.

- Safety: Glass safety housing with autolock function for operator protection. Casting dish monitors prevent flux spills.

- Robust: Patented FluxInert® ceramic holders resistant to flux.

- Highest precision: bottom-loading closed furnace design offers best temperature control.

- High speed mixing: Unique high-speed 3D sample rotation gives best mixing for reproducible fusions.

- Autosampler options: multiple autosampler options for increased throughput

- ICP option: allows fusion with metaborate and pouring into beakers for ICP/AAS analysis.

- New High-throughput system: VITRIOX® Electric 4+ large furnace design with capacity to fuse 4 samples simultaneously.

VITRIOX® Electric Fusion Systems Product Video

Playlist

2:21

2:05

About the VITRIOX® Electric Fusion Systems

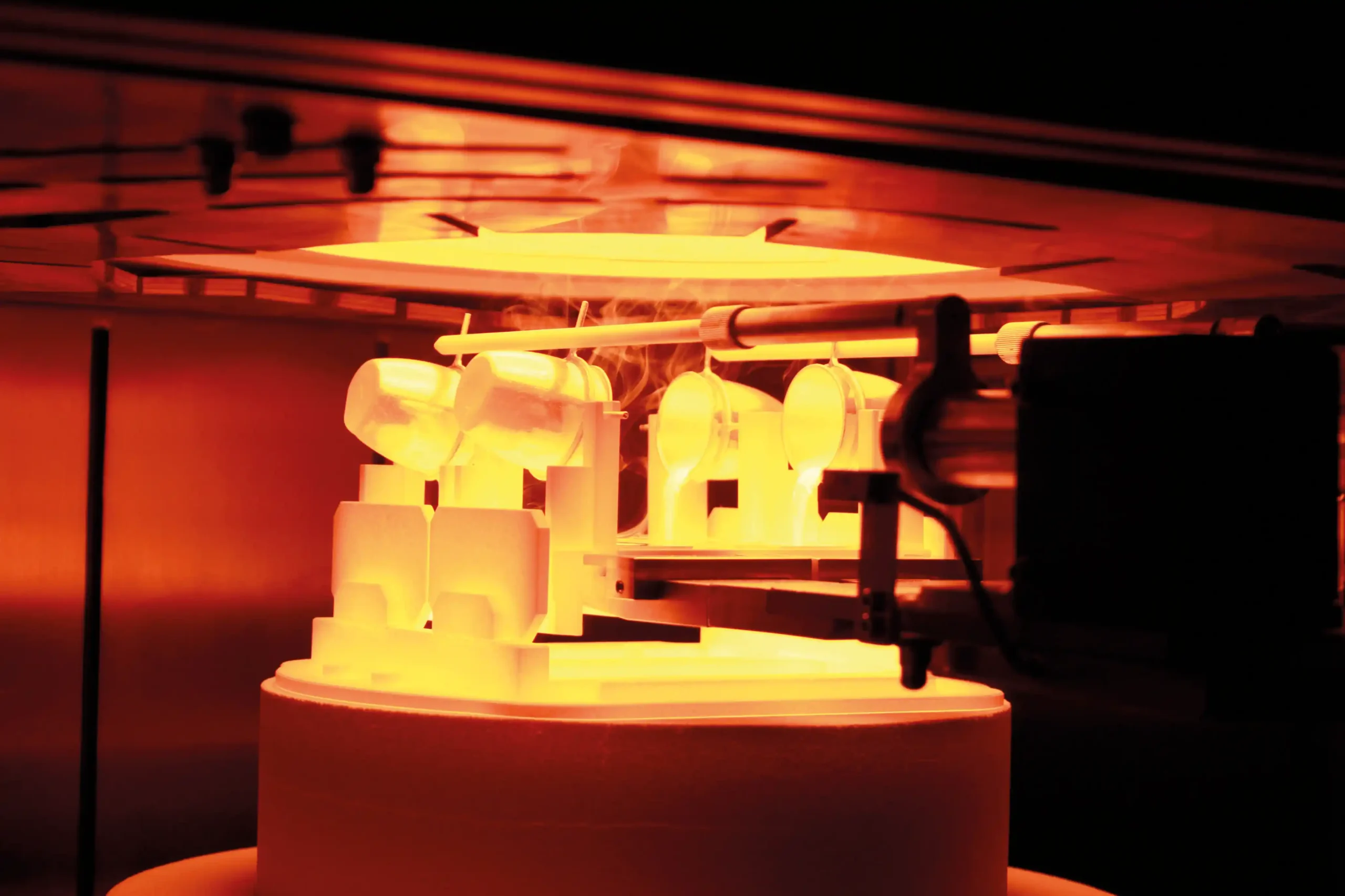

Introducing the VITRIOX® Electric range of automated fusion systems from Fluxana, a groundbreaking solution designed to meet the demands of modern laboratories, providing fully automated “cold to cold” fusion in an enclosed furnace designed to offer the ultimate in precision and repeatability.

Underpinned by years of research and development and Fluxana’s in-depth understanding of industry needs, at the heart of the system is its unique furnace design.

The upright cylindrical furnace with samples centred in the chamber ensures that every fusion is exposed to near-identical fusion conditions.

This results in fusions which are unrivalled for precision and reproducibility. The VITRIOX® Electric system offers a multitude of unique or beneficial features such as its high-speed rotation mechanism for the best sample homogenisation, patented FluxInert® flux-resistant ceramic holders, casting dish monitors to prevent flux spills, and locking safety cabinet for operator protection.

An autosampler options allow queueing of sample batches and continuous operation speeds up throughput by allowing simultaneous fusion and cooling of different samples.

If the autosampler extensions available with the standard VITRIOX® Electric are still not enough, then the VITRIOX® Electric 4+ offers an additional dimension: simultaneous fusion of up to four samples per cycle.

The large chamber furnace and 4-position sample holder are designed to increase capacity without compromising the precision and reproducibility at the heart of the VITRIOX® range.

An autosampler system allows queueing of up to 16 samples at a time.

Suitable for any sample types that can be fused, including cements, ores, geological samples, ashes and industrial products, the VITRIOX® electric range provides sample preparation that is more representative, more reproducible, safer, and more efficient.

Underpinned by Fluxana’s vast experience of XRF fusion and available in conjunction with application packages for a wide variety of materials, the VITRIOX® Electric range offers a truly complete solution for XRF fused bead preparation.

"The VITRIOX ELECTRIC 4 from FLUXANA ensures unparalleled consistency and

safety in sample preparation with its advanced electric fusion system for XRF analysis."

Product FAQ's

Any sample that is compatible with borate fusion, including cement, ores, geological samples, manufactured chemicals, and industrial products such as slags and ashes.

By providing uniform, consistent fused beads, it ensures higher accuracy and reliability in XRF analysis results.

Yes, its user-friendly operation and software are designed for easy integration into current laboratory setups and workflows.

The VITRIOX® Electric has extensive safety features. The hot area is enclosed in a glass safety cabinet that locks during operation. Casting dish sensors ensure mould are positioned before starting the fusion, preventing spillages. The furnace is equipped with backup thermocouples to eliminate the risk of furnace overheating.

Minimal training is needed due to its intuitive design and user-friendly software, making it accessible for all levels of laboratory personnel.

Applications

Contact Us Today

We take great pleasure in assisting you and ensuring you get a prompt response to your questions

Live chat opening hours Mon – Fri 9:15 to 16:30 (UK Time)