Home » Products » Petroleum Testing » TO10

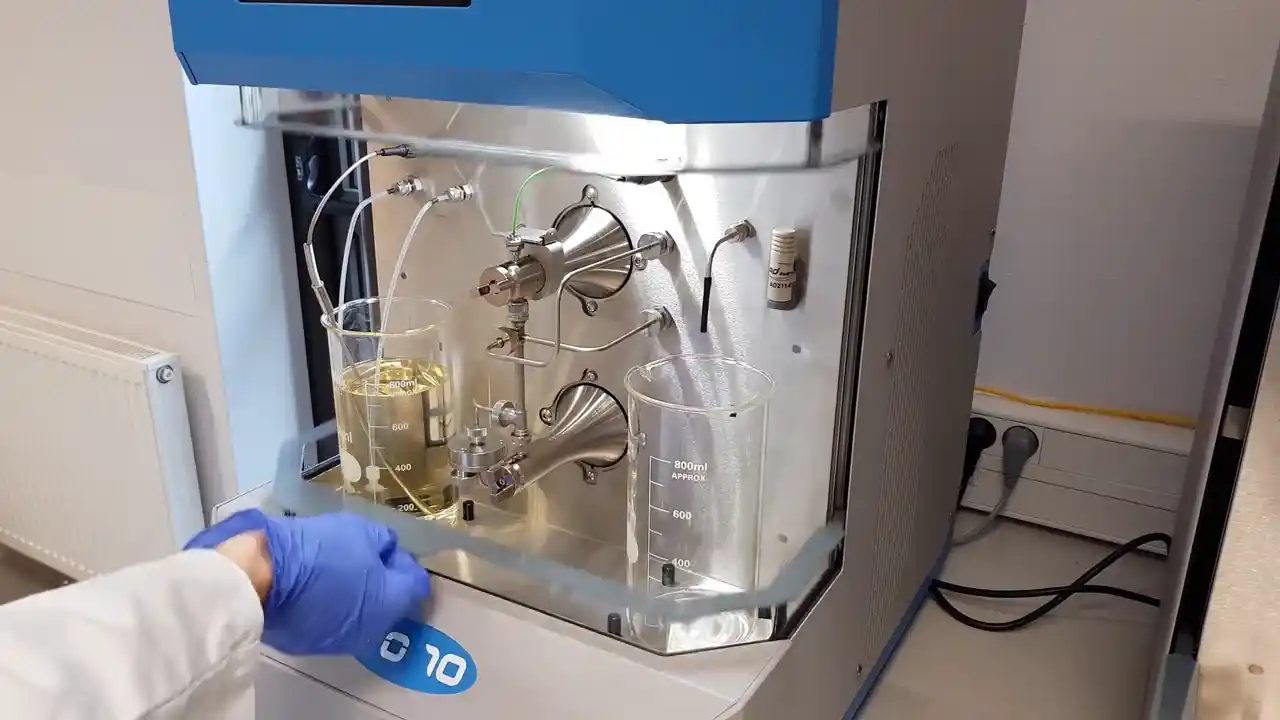

TO10 Thermal Oxidation Stability Test Rig

The TO10 Thermal Oxidation Stability Tester delivers precise, automated jet fuel thermal oxidation testing, ensuring compliance and boosting laboratory productivity.

Product Overview

The TO10 Thermal Oxidation Stability Tester is an advanced solution for jet fuel thermal oxidation testing. It offers fully automated performance for ease and repeatability.

Designed to measure the thermal oxidation stability of aviation turbine fuels. Compliant with ASTM D3241, IP 323, ISO 6249, and DEF STAN 91-091.

Built for use in both military and civilian fuel testing environments. Suitable for synthetic and conventional jet fuel analysis. Equipped with real-time monitoring and rapid cooling. Compatible with the DR10 ITR tube deposit rater for seamless integration. Delivers precision and reliability in every test.

Features & Benefits

Real-Time Oversight – Monitors every test condition.

Wide Temperature Range – 100°C to 380°C.

Pulse-Free Fuel Delivery – Dual 5 mL syringes.

Operator Safety First – Enclosed vapour control.

Key applications

- Fully Automated Operation – Enables consistent, repeatable jet fuel testing.

- ASTM D3241 Compliant – Ensures accuracy to industry-approved standards.

- Tool-Free Heater Tube Positioning – No need for manual adjustments.

- DR10 Integration – Allows seamless fuel tube deposit rating.

- Real-Time Monitoring – Intelligent software oversees every parameter.

- Dual Syringe Fuel Flow – Pulse-free 5 mL syringe system for precision.

- Rapid Cooling Function – Reduces downtime between tests.

- Intuitive User Interface – Simple operation for all experience levels.

- Flexible Temperature Range – Operates between 100°C to 380°C.

- Sealed Vapour Handling – Includes fume extraction and safety door.

TO10 Thermal Oxidation Stability Test Rig Product Video

About the TO10 Thermal Oxidation Stability Test Rig

The TO10 Thermal Oxidation Stability Tester is redefining aviation fuel testing by addressing a critical challenge faced by laboratories and quality control teams: the need for precision, compliance, and ease of operation in jet fuel analysis. Traditionally, evaluating the thermal oxidation stability of aviation fuels required time-consuming setups, manual interventions, and potential safety risks. The TO10 eliminates these pain points with a purpose-built, automated system that ensures both accurate results and streamlined workflow.

This next-generation jet fuel thermal stability analyser is engineered for use in refineries, military fuel labs, and research centres. It supports rigorous industry standards, including ASTM D3241, IP 323, ISO 6249, ASTM D1655, ASTM D7566, and DEF STAN 91-091 jet fuel testing. Whether you’re examining synthetic jet fuels or traditional kerosene-based blends, the TO10’s wide temperature range from 100°C to 380°C accommodates a variety of applications.

Ease of use is at the forefront of the TO10’s design. The instrument features automatic heater tube positioning, eliminating the need for tools and reducing setup time. Laboratories can operate with confidence, knowing the TO10’s intelligent software continuously monitors test conditions in real-time, providing unmatched control and reliability throughout every analysis cycle.

Safety and operational efficiency go hand-in-hand. With its sealed vapour handling system, integrated fume extraction, and protective safety door, the TO10 prioritises operator safety without compromising test accuracy. Its dual 5 mL syringe fuel delivery system ensures a pulse-free flow, leading to consistent test outcomes, while the rapid cooling function dramatically increases throughput by reducing wait times between analyses.

The TO10 Thermal Oxidation Stability Tester is redefining aviation fuel testing by addressing a critical challenge faced by laboratories and quality control teams: the need for precision, compliance, and ease of operation in jet fuel analysis. Traditionally, evaluating the thermal oxidation stability of aviation fuels required time-consuming setups, manual interventions, and potential safety risks. The TO10 eliminates these pain points with a purpose-built, automated system that ensures both accurate results and streamlined workflow.

This next-generation jet fuel thermal stability analyser is engineered for use in refineries, military fuel labs, and research centres. It supports rigorous industry standards, including ASTM D3241, IP 323, ISO 6249, ASTM D1655, ASTM D7566, and DEF STAN 91-091 jet fuel testing. Whether you’re examining synthetic jet fuels or traditional kerosene-based blends, the TO10’s wide temperature range from 100°C to 380°C accommodates a variety of applications.

"The TO10 is an automated jet fuel oxidation stability tester with real-time

monitoring and DR10 integration for deposit analysis."

Product FAQ's

It measures the thermal oxidation stability of aviation turbine fuels.

It complies with ASTM D3241, ASTM D1655, ASTM D7566, IP 323, ISO 6249, and DEF STAN 91-091.

Yes, its wide temperature range makes it ideal for both conventional and synthetic fuels.

Yes, it integrates directly with the DR10 ITR tube rate for integrated fuel tube deposit rating.

The system includes a sealed test chamber, vapour extraction, and a safety door to eliminate exposure risks.

Applications

Application Note 1

Application Note 2

Application Note 3

Contact Us Today

We take great pleasure in assisting you and ensuring you get a prompt response to your questions

Live chat opening hours Mon – Fri 9:15 to 16:30 (UK Time)