Home » Products » Process Safety Solutions » Power Compensation Reaction Calorimeter

Power Compensation Reaction Calorimeter

The Power Compensation Reaction Calorimeter combines advanced enthalpy and process power analysis with revolutionary calorimetry technology for accurate reaction enthalpy determination and process power quantification.

Product Overview

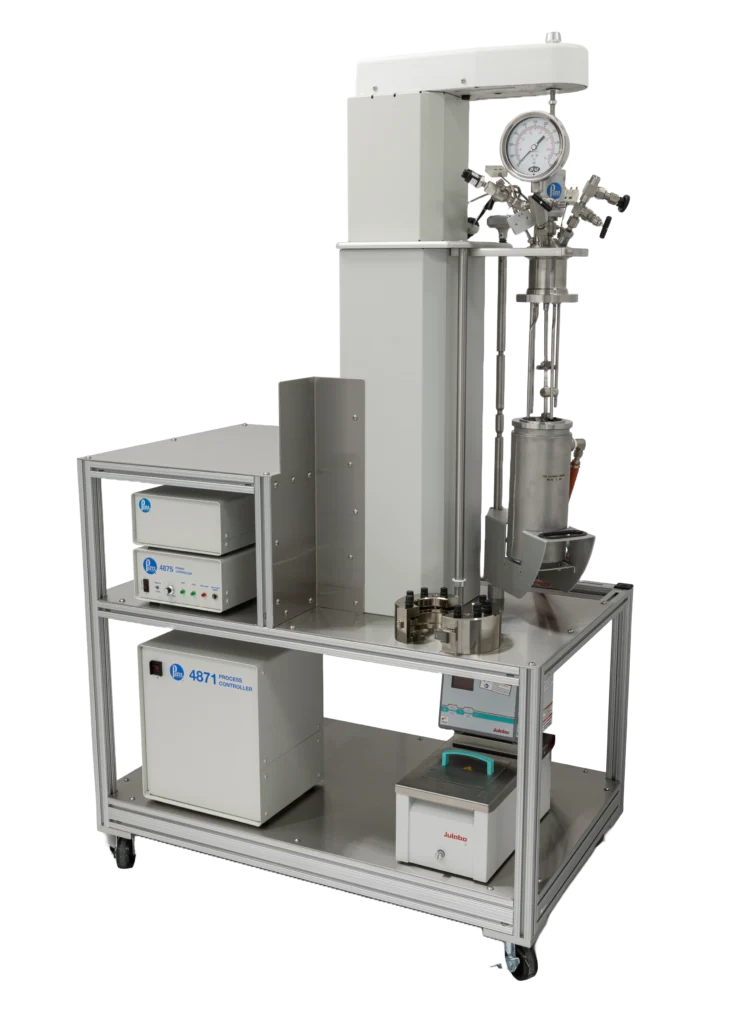

The Power Compensation Reaction Calorimeter is a cutting-edge tool designed to determine reaction enthalpy using power compensation calorimetry. Developed by Parr Instrument Company, this innovative technique offers a direct and intuitive way to quantify process power and calculate the enthalpy of chemical reactions. With its ability to attain thermal equilibrium rapidly, it’s advantageous for measuring heat flow from short-lived reactions, making it essential for chemical reaction monitoring.

Features & Benefits

Enthalpy Determination

Accurate and Direct

Isothermally Controlled

Precise Temperature Regulation

Parr 4871 Controller

Seamless Operation Coordination

Key applications

- Reaction Enthalpy Determination: Accurate measurement of reaction heat.

- Process Power Quantification: Direct method to quantify process power.

- Reaction Vessel with Circulating Jacket: Isothermally controlled for precise temperature regulation.

- Compensation or Trim Heater: Automatically varies electrical power to maintain desired process temperature.

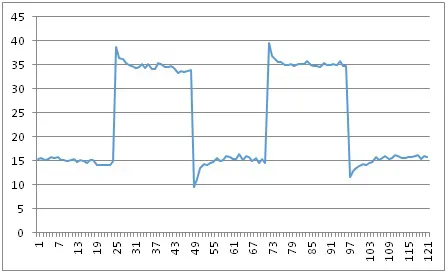

- Electrical Power Variation: Determines heat liberated or absorbed by the process.

- Thermal Equilibrium: Attains equilibrium more quickly than other calorimeters.

- Cooling Power Estimation: Essential for maintaining safe and effective process conditions.

- Parr 4871 Process Controller: Controls and coordinates the overall operation.

- Jacketed Vessel: With a constant temperature circulating bath.

- Heat Flow Measurement: For in-depth reaction mechanisms and kinetics study

Power Compensation Reaction Calorimeter Product Video

About the Power Compensation Reaction Calorimeter

In the complex world of chemical research and development, understanding the enthalpy of reactions and the power involved in the process is crucial. The Power Compensation Reaction Calorimeter, a product of the collaboration between SciMed and Parr Instrument Company, addresses this need.

The calorimeter’s unique ability to determine reaction enthalpy using power compensation calorimetry sets it apart. This method offers a direct and intuitive way to quantify process power, calculate the enthalpy of the reaction, and study factors influencing reaction mechanisms and kinetics.

The system’s reaction vessel, equipped with a circulating jacket, is isothermally controlled, ensuring precise temperature regulation. The compensation or trim heater, which automatically varies its electrical power, maintains the desired process temperature as the process heat load changes.

This feature allows the calorimeter to attain thermal equilibrium more quickly than other calorimeters, making it advantageous for measuring heat flow from short-lived reactions.

Furthermore, the Power Compensation Reaction Calorimeter provides cooling power estimation, essential for maintaining safe and effective process conditions. The integration of the Parr 4871 Process Controller ensures seamless control and coordination of the system.

Whether it’s a chemical research laboratory exploring new compounds, a pharmaceutical company developing new drugs, or an academic institution teaching the principles of calorimetry, the Power Compensation Reaction Calorimeter offers a robust and user-friendly solution. Its high performance, precision, and innovative features make it an invaluable asset for anyone involved in chemical reaction monitoring.

"Parr Instrument Company's Power Compensation Reaction Calorimeter

is designed for precise heat flow and reaction energy measurements,

suitable for both research and industrial use."

Applications

Application Note 1

Application Note 2

Application Note 3

Product FAQ's

The calorimeter offers a direct method to quantify process power and calculate reaction enthalpy, with quick thermal equilibrium and precise temperature control.

The trim heater automatically varies its electrical power to maintain the desired process temperature, adapting to the process heat load changes.

Yes, it attains thermal equilibrium more rapidly than other calorimeters, making it advantageous for measuring heat flow from short-lived reactions.

The Parr 4871 Process Controller controls and coordinates the overall operation of the system, ensuring seamless functionality.

Yes, it can establish the cooling power needed to maintain safe and effective process conditions.

Contact Us Today

We take great pleasure in assisting you and ensuring you get a prompt response to your questions

Live chat opening hours Mon – Fri 9:15 to 16:30 (UK Time)