Home » Products » Oil Condition Monitoring » Complete Oil Analysis Laboratory » MiniLab Series

MiniLab Series

The MiniLab Series delivers comprehensive on-site oil analysis, providing immediate actionable results, saving time and reducing costs.

Product Overview

The MiniLab Series is a comprehensive oil analysis lab designed for industrial plants, power plants, aviation, rail fleet, high-performance engines and more. Condition based oil monitoring is vital to any effective lubrication program and the MiniLab integrates four simple tests to inform on all key parameters for oil and machinery condition including fluid chemistry, viscosity, and machine wear.

In less than 15 minutes, maintenance professionals are provided with immediate and actionable results that save time, reduce costs and maximise uptime for critical and high-value machinery assets.

Features & Benefits

Elemental analysis

Accurate measurement of 24 elements to identify contaminants, wear metals and additive compositions.

Particle count and ferrous monitor

Direct laser imaging and magnetic coils provides particle count, ISO codes, wear classifications, and total ferrous measurement.

Fluid chemistry

Infrared (IR) spectrometer measures Total Acid Number (TAN), Total Base Number (TBN), oxidation, glycol, soot, water and more.

Key applications of the LaserNet

- One product, delivering lab-quality data outside of the lab.

- Designed for the non-expert user, no chemist is required.

- ASTM compliant: Meets standards such as ASTM D6595, ASTM D7889, ASTM D8092, and more, with traceable validation fluids included.

- TruVu 360 Software Integration: Cloud-hosted or local installation for sample scheduling, instrument operation, data acquisition, and maintenance reporting.

- Customisable alarm limits & diagnostics: Maintenance professionals can define their own warning parameters and generate automated diagnostics for immediate actions.

- Modular design: The MiniLab series integrates four modular instruments, each available individually to allow a bespoke configuration to suit industry needs.

MiniLab Series Product Video

Playlist

3:22

2:22

About the MiniLab Series

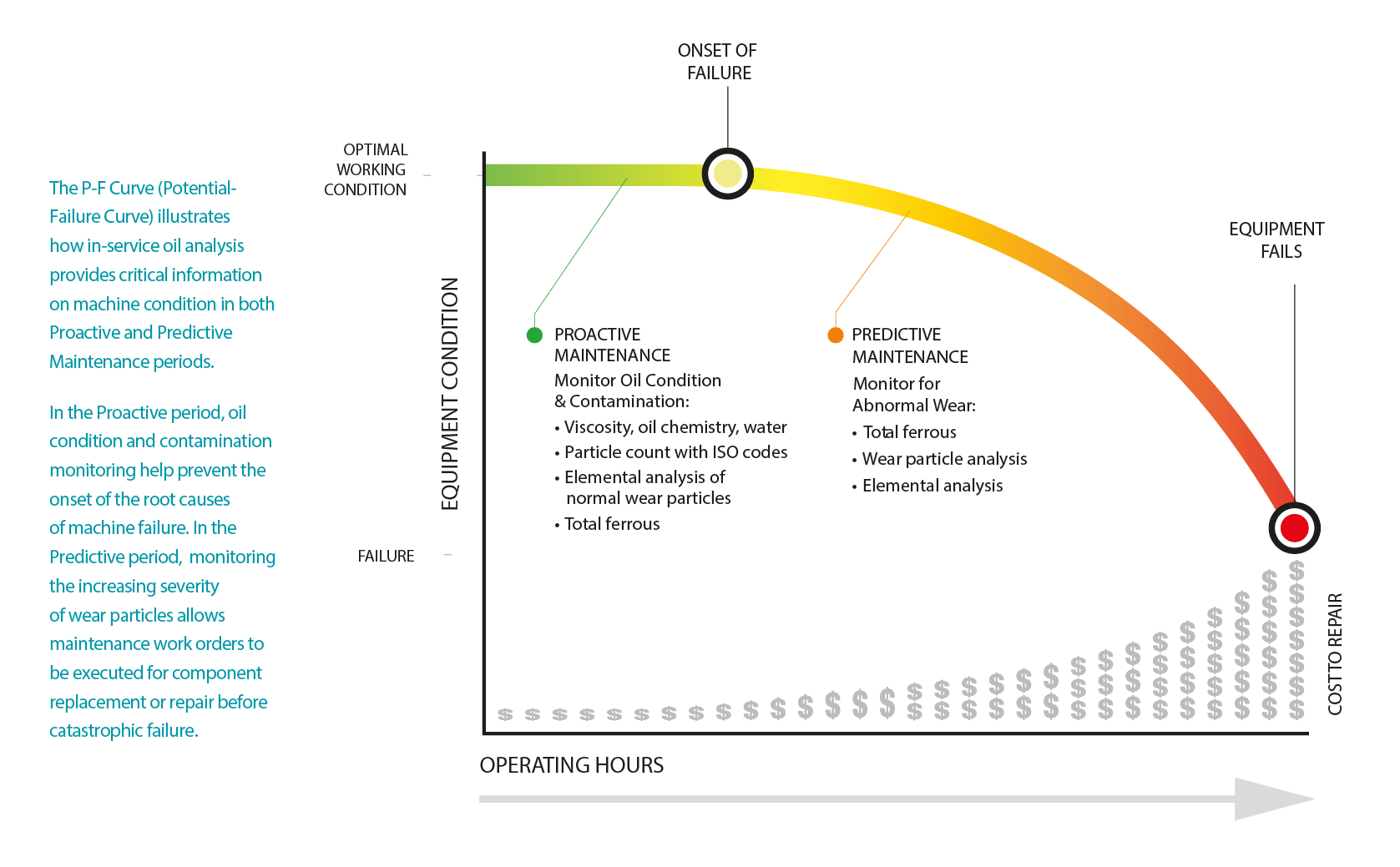

The reliable performance of high-value machinery assets is critical to all industrial operations. Condition based oil monitoring is vital to any effective lubrication program and allows for a more proactive approach to asset maintenance.

The MiniLab series complements traditional vibration, thermography, and other predictive maintenance technologies by bringing laboratory-quality oil analysis on-site outside of the lab environment. This allows maintenance professionals to take control of their oil analysis in a wide-range of sectors including industrial plants, power plants, aviation, vehicle fleet, high-performance engines and more.

By closing the feedback loop between on-site maintenance engineers and the oil analysis lab; maintenance actions can be taken in a targeted and efficient manner. This offers a variety of benefits including:

Reduced lubricant usage: Condition-based oil monitoring can extend drain intervals and avoid unnecessary fluid changes.

Reduced maintenance costs: Early identification of abnormal operation can facilitate immediate maintenance actions and avoid costly downtime or repairs.

Improved Carbon Footprint: Studies show that lubricant change and disposal can generate ≥2.5 kg of CO2 per litre. Extending fluid life and reducing maintenance and labour costs can see industries make a meaningful impact to their carbon footprint.

The MiniLab series offers a simplified workflow and user-friendly software to facilitate the scheduling of samples, instrument operation, data acquisition and maintenance reporting all with no need for a chemist or lab expertise. The modular design integrates four simple tests to inform on all key parameters for oil and machinery condition including fluid chemistry, viscosity, and machine wear. In less than 15 minutes, maintenance professionals are provided with immediate and actionable results that save time, reduce costs and maximise uptime for critical and high-value machinery assets.

In conclusion, the MiniLab Series is more than just an oil analyser; it’s a comprehensive solution that ensures quality, efficiency, and adaptability across various fields. Its unique combination of features and benefits positions it as a leading solution for those seeking excellence in on-site oil analysis and machinery asset monitoring.

"The MiniLab Series from Spectro Scientific is a versatile

on-site oil analysis system, ideal for quick, actionable machine

condition monitoring in industrial settings."

Product FAQ's

The MiniLab 153 Series is ideal for racing, aviation, rail fleet, and various industrial machinery applications.

Yes, it meets various ASTM standards such as ASTM D6595, ASTM D7889, and more.

The MiniLab 153 Series integrates with TruVu 360 Software for enhanced control and data handling.

It offers elemental analysis, viscosity measurement, fuel dilution, total ferrous detection, and contamination analysis.

Yes, sample preparation equipment and consumables for 100 samples are included.

Applications

Application Note 1

Application Note 2

Application Note 3

Contact Us Today

We take great pleasure in assisting you and ensuring you get a prompt response to your questions

Live chat opening hours Mon – Fri 9:15 to 16:30 (UK Time)