Home » Products » Oil Condition Monitoring » Wear Debris Analyser » LaserNet 200 Series

LaserNet 200 Series

The LaserNet 200 Series offers advanced predictive maintenance through precise wear particle analysis, ISO 4406 coding, and wear type classification.

Product Overview

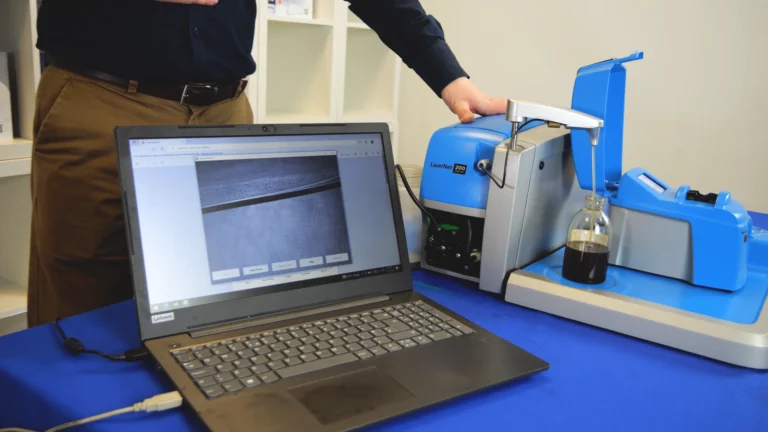

The LaserNet 200 Series is a state-of-the-art wear debris analyzer designed to revolutionise predictive maintenance in various industrial applications. Compliant with ASTM D7596, it provides detailed particle count and size distribution, ISO 4406 coding, ferrous concentration measurement, and classifies particles into categories like cutting wear, sliding wear, and fatigue wear. This allows maintenance engineers to take immediate and targeted action to remedy any developing abnormal machine wear.

The direct laser imaging and wide-ranging capability are unparalleled allowing the analysis of dark fluids (up to 2% soot content) and viscosities up to 320 cSt without dilution.

Features & Benefits

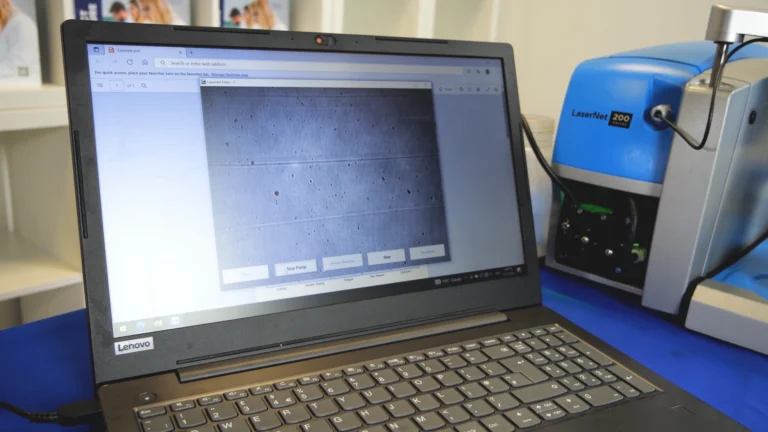

Direct laser imaging

Precise analysis for particle count, size distributions and codes (ISO 4406, NAS 1638, NAVAIR, SAE and more)

Widest capability range

Highest saturation limit (up to 10 million particles/ml) and analyse dark fluids and viscosities up to 320 cSt without dilution.

Recognise non-ferrous debris

Automated corrections for water and air bubbles and automated identification of non-ferrous debris such as dust and fibres.

Key applications of the LaserNet

- Particle Cleanliness Codes Compliance: Adheres to ISO 4406, ASTM D6786.

- Direct Imaging Particle Analyzer: Widest range of capability compared with other particle counters. Allowing analysis of up to 10 million particles/ml, dark fluids with up to 2% soot, error correction for water and air bubbles, and up to 320 cSt without dilution

- ASTM D7596 Compliant: Standard Test Method for Automatic Particle Counting and Particle Shape Classification of Oils Using a Direct Imaging Integrated Tester, complete with traceable validation fluids.

- Cutting Wear, Sliding Wear, Fatigue Wear Classification: Detailed insights into wear types for targeted maintenance actions.

- Automated Ferrous analysis: Comprehensive analysis of ferrous wear particles and ferrous wear severity index (FWSI).

- Auto-Sampler Option: Enables unattended operation for high throughput.

LaserNet 200 Series Product Video

Playlist

3:20

3:11

About the LaserNet 200 Series

The LaserNet 200 Series is not just a product; it’s a solution to the complex challenges faced by industries in the realm of predictive maintenance and addressing abnormal machine wear. In an era where machinery efficiency and lifespan are paramount, understanding wear and tear at a microscopic level becomes essential.

The introduction of the LaserNet 200 Series has marked a significant advancement in wear debris analysis. Its ability to classify particles into cutting wear, sliding wear, and fatigue wear, coupled with the Ferrous Wear Severity Index (FWSI), provides a detailed understanding of machinery health. This information is vital for timely interventions, reducing downtime, and enhancing overall productivity.

What sets the LaserNet 200 Series apart is its integration of cutting-edge technologies like direct laser imaging particle analysis, neural network classification, and automated ferrography. These features not only ensure accuracy but also provide visual confirmation, making the analysis more transparent and reliable.

Its compliance with various particle cleanliness codes like ISO 4406 and ASTM D6786 ensures that the analysis is standardized and universally applicable. The auto-sampler option also adds to its efficiency, allowing for unattended operation and high throughput.

In essence, the LaserNet 200 Series is a comprehensive tool that empowers industries to take control of their machinery health. It’s not just about detecting problems; it’s about understanding them at their core and taking informed actions that align with long-term goals and sustainability.

"The LaserNet 200 Series is a sophisticated particle analyser for lubricants,

enhancing machine condition monitoring with detailed wear debris analysis"

Product FAQ's

It’s designed for wear debris analysis, providing insights for predictive maintenance.

Yes, it complies with ASTM D7596, ISO 4406, and ASTM D6786.

Yes, it classifies particles into cutting wear, sliding wear, and fatigue wear.

The direct laser imaging offers the widest capability range including the analysis of dark/dirty fluids and high viscosities with no need for dilution.

It allows for unattended operation, enabling high throughput and efficiency.

Applications

Application Note 1

Application Note 2

Application Note 3

Contact Us Today

We take great pleasure in assisting you and ensuring you get a prompt response to your questions

Live chat opening hours Mon – Fri 9:15 to 16:30 (UK Time)