Home » Products » Petroleum Testing » Automatic Air Release Analyser » K88539 Automated Air Release Analyser

K88539 Automated Air Release Analyser

The K88539 Automated Air Release Value Apparatus, with its integrated Touch Screen Control Panel, guides the user throughout the Automated Air Release test and automatically measures the time for air release.

It conforms to ASTM D3427, IP 313 and related specifications.

Product Overview

The Koehler Air Release Value Apparatus incorporates an automatic lift system, integrated industrial touchscreen and internal balance, enabling it to provide automatic calculation of the air release value.

It consists of a test vessel and airflow control equipment which deliver heated air at the specified flow rate to the oil sample which is maintained at constant temperature. The integrated touch screen guides the user throughout the whole process and provides density calculation and timing operation for measuring the air release value of the test sample.

To determine air release properties, the sample is heated to a specified temperature and blown with compressed air – the temperature and timings set by a prescribed method such as ASTM 3427.

Features & Benefits

Automatic Lift System

Industrial touchscreen user interface

Key Applications

- Conforms to ASTM D3427, IP 313 and related specifications

- Integrated Touch Screen Control Panel with windows PC

- Automatic Lift System that moves the test vessel from the air source to the balance sinker

- Automatic calculation of the final sample density for determination of the air release value

- Integrated Circulation Bath with a water level indicator

- Integrated Balance

- Secure Clamp Mechanism of the air tube

- Automated Jacketed Test Vessel draining

- Integrated sample preheater

- Safety Shield

- LIMS Compatibility

- Compressed air heater, overtemperature and overpressure protection circuitry.

- Sample temperature up to 75°C

- Option for external chiller

- Drying oven is available as additional accessory for warming the test oil at temperatures of up to 100°C;

K88539 Automated Air Release Analyser Product Video

About the K88539 Automated Air Release Analyser

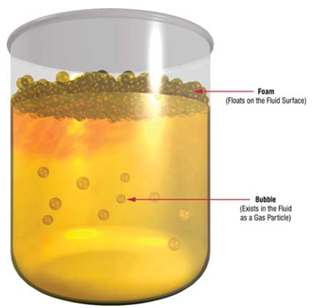

Oil in equipment which moves, such as bearings, gears, pumps and couplings, may produce a dispersion of finely divided air bubbles in the oil.

If these air bubbles do not have time to raise to the surface whilst in the reservoir, then a mixture of oil and air will circulate throughout the lubricating system which can result in issues such as incomplete oil films in couplings and bearings, and in pumps an inability to maintain oil pressure.

The instrument houses a touch screen display from which the whole test can be controlled. The waterbath for heating the oil to the correct temperature is housed inside the instrument, with a water level indicator at the front for easy checking and filling of the bath.

Compressed air enters the instrument on the side and controlled from the instrument by a regulator housed on the front.

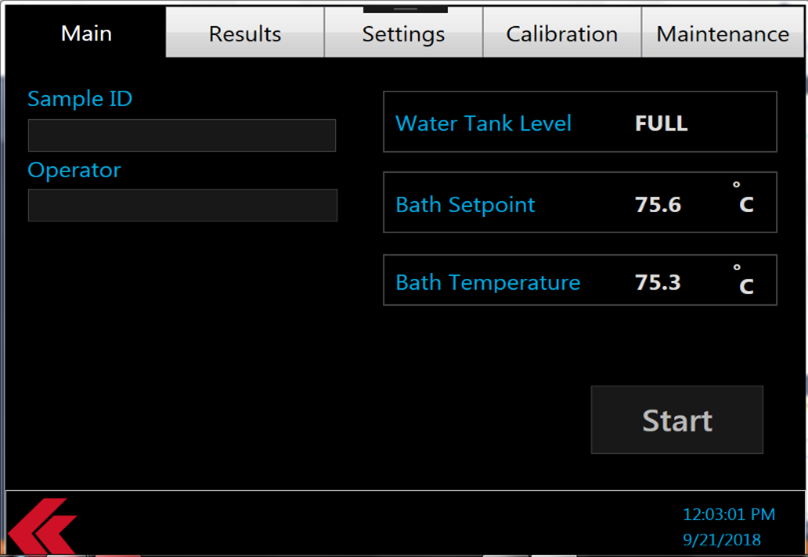

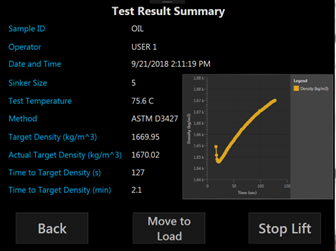

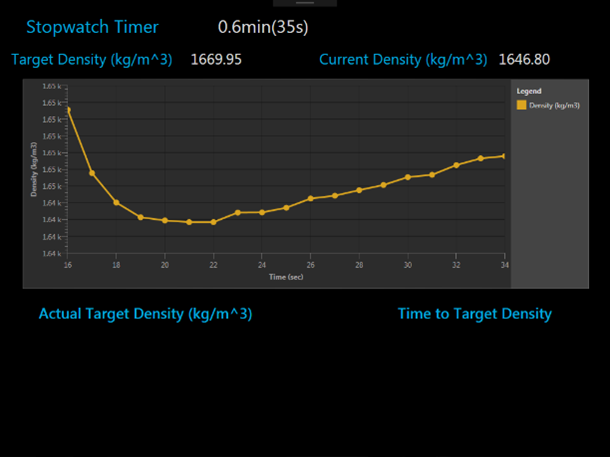

The Integrated touch screen control panel guides the user throughout the test. From the front panel the user can enter the sample identity and the operator name.

The Results tab is where all of the stored test data can be accessed.

The Systems Settings screen gives general information about the unit and software. The Test Settings screen is where the user can select the Temperature Units, Water/Air Temperature, Sinker Size being used, Initial Sample Warming Time and Glassware Preheat Time.

Within the Calibration Tab there is a tab for Ticket Summary which gives an overall calibration summary that can easily be printed. The calibration summary clearly shows the water temperature calibration offsets as well as the air temperature calibration offsets. The other tab is the Temperature Calibration Tab. Here is where the offset values at the different temperature points (in Celsius) can be entered.

The maintenance tab shows the overall instrument performance such as: bath temperature, air temperature, water tank level, mass reading, pressure, sample temperature, etc. From here the balance can be tared, the lift can be brought to its different positions and the air pump can be switched on and off for general maintenance purposes.

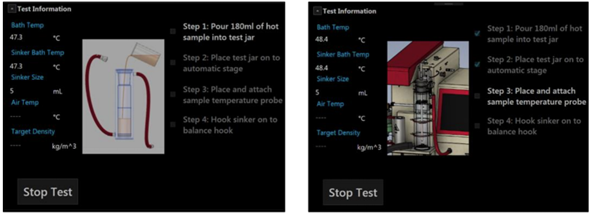

Once started the method talks the operator through each step that has to be performed:

The K88530 Automated Air Release Value instrument is shipped as a complete unit, requiring only compressed air, and water in the waterbath, to be able to run a test.

When the test has finished the results are stored and can be accessed through the software or exported.

Specifications:

• Temperature Range: Ambient to 75 °C

• Sample Temperature Stability: ±0.1 °C

• Air Temperature Stability: ±0.2 °C

• Density: ±0.001 g/mL

• Used for the following oils: turbine, hydraulic, lubricating, gear, synthetic, hydrocarbon, pump and bearing

The instrument requires compressed air.

The Koehler Automated Air Release Value includes the below accessories:

- Sinkers, 5mL and 10mL

- Integrated Balance

- Integrated Circulator

- Air Bath for Sinker

- Tubing and Fittings

- Platinum Wire

"The Koehler Automated Air Release Value Analyser delivers fast,

accurate air release measurements for lubricating oils,

ensuring quality and standards compliance."

Product FAQ's

Samples analysed by the Air Release include: turbine, hydraulic, lubricating, gear, synthetic, hydrocarbon, pump and bearing oils.

Yes the software is loaded onto the instrument and is designed specifically to follow ASTM D3427.

Yes, the instrument will calculate the final sample density for the determination of the air release value.

The instrument requires compressed air.

The instrument has an integrated balance to perform the test.

Applications

Contact Us Today

We take great pleasure in assisting you and ensuring you get a prompt response to your questions

Live chat opening hours Mon – Fri 9:15 to 16:30 (UK Time)