Home » Products » Petroleum Testing » Flow Loop Systems

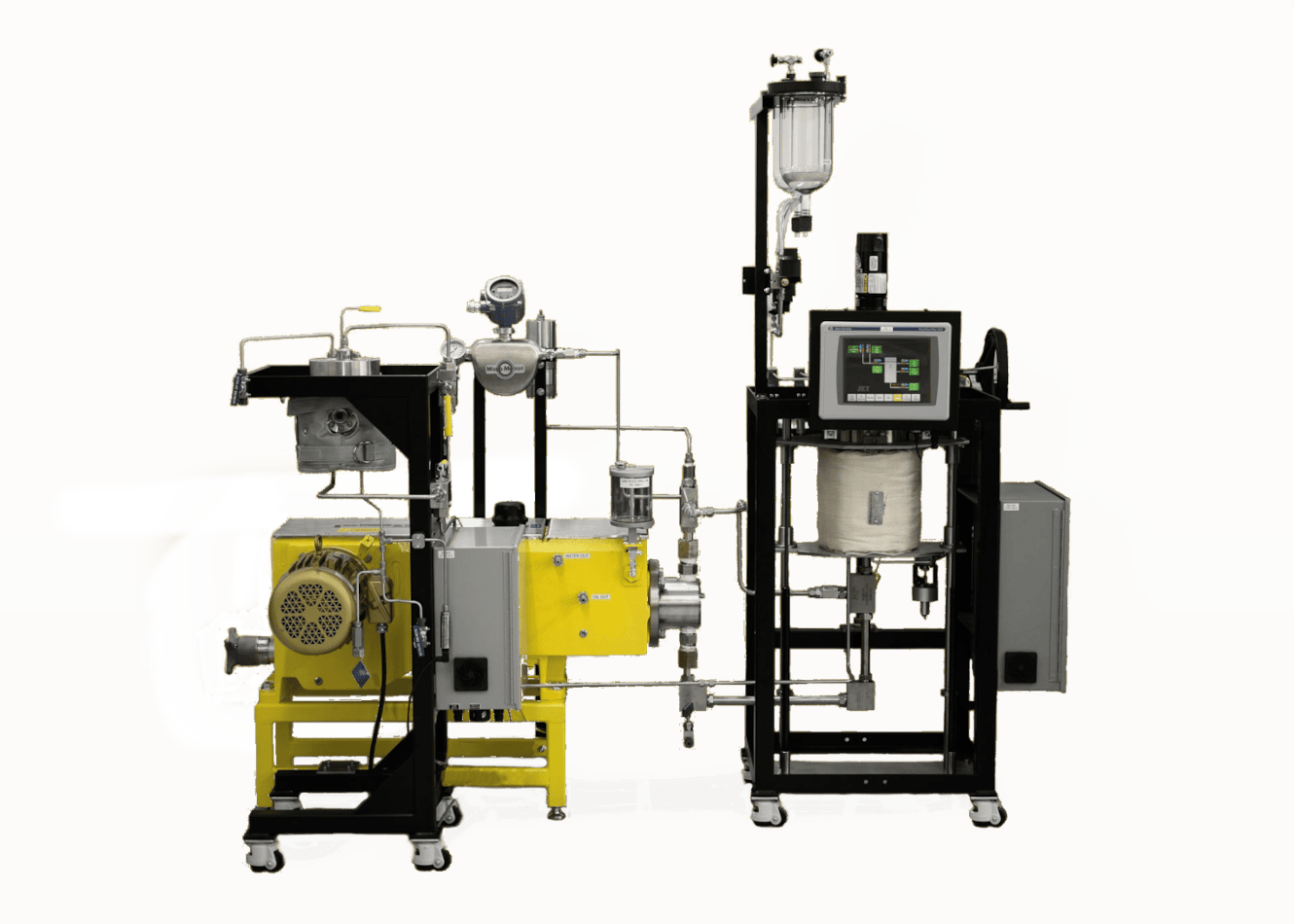

Advanced Flow Loop Systems for Pipeline Flow Simulation

High-precision flow loop systems for single-phase and multiphase flow testing, pipeline simulation, and corrosion analysis in research applications.

Product Overview

Our flow loop systems provide cutting-edge solutions for pipeline flow simulation, corrosion analysis, and multiphase flow research.

Designed for single-phase liquid flow testing, single-phase gas flow testing, and complex multiphase flow systems, these units simulate real-world pipeline conditions with unmatched precision. Equipped with variable speed pumps, removable test sections, and in-line test spool sections, these systems facilitate comprehensive testing for corrosion inhibitor evaluation, drag reducer effectiveness testing, and slug flow testing.

Whether for annular flow simulation, laminar flow studies, or stratified flow analysis, our flow loop systems deliver the accuracy and reliability required for high-quality research and industrial applications.

Features & Benefits

Realistic Pipeline Simulation: Accurately replicates flow conditions.

Realistic Pipeline Simulation: Accurately replicates flow conditions.

Customisable Flow Regimes: Supports slug, annular, and stratified flow studies.

Optimised Flow Control: Variable speed pumps for precise adjustments.

Key applications

- Flow Loop Systems: Designed for high-accuracy pipeline simulation.

- Pipeline Flow Simulation: Mimics real-world pipeline conditions for research and development.

- Single-Phase Liquid Flow Testing: Enables precise fluid behaviour analysis.

- Single-Phase Gas Flow Testing: Facilitates gas-phase research with controlled parameters.

- Multiphase Flow Systems: Supports complex interactions between liquid and gas phases.

- Laminar Flow Simulation: Studies fluid behaviour under low Reynolds numbers.

- Corrosion Flow Analysis: Evaluates material degradation in different flow environments.

- Slug Flow Testing: Analyses irregular liquid and gas interactions in pipelines.

- Annular Flow Simulation: Assesses flow regimes crucial for industrial applications.

- Stratified Flow Analysis: Provides insights into separated fluid flow conditions.

- Corrosion Inhibitor Evaluation: Tests the effectiveness of protective treatments.

- Drag Reducer Effectiveness Testing: Determines the impact of additives on pipeline efficiency.

- Variable Speed Pumps: Allows precise control over flow rates.

- In-Line Test Spool Sections: Enables accurate and adaptable experimental setups.

- Removable Test Sections: Facilitates easy modifications and enhanced flexibility in research.

VD10 Automatic Video Distillation Analyser Product Video

About the Flow Loop Systems

Fluid dynamics play a critical role in a wide range of industries, from oil and gas to chemical processing and material science. Understanding how fluids behave under different conditions is crucial for optimising performance, ensuring safety, and improving efficiency. Flow loop systems are fundamental to this research, enabling scientists and engineers to simulate real-world flow conditions and test material integrity under various scenarios.

Our advanced flow loop systems address these challenges by offering a high-precision platform for studying single-phase liquid flow, single-phase gas flow, and multiphase interactions. These systems allow researchers to replicate and analyse pipeline flow simulation, corrosion flow analysis, and shear stress impact on materials. With dedicated capabilities for laminar flow simulation, slug flow testing, annular flow simulation, and stratified flow analysis, our flow loops offer unparalleled testing flexibility.

One of the primary concerns in pipeline and industrial fluid research is corrosion. The impact of fluid movement on material degradation must be well understood to improve pipeline longevity and safety. Our corrosion inhibitor evaluation and corrosion flow analysis functionalities provide researchers with an essential toolkit to measure and optimise protective solutions. The addition of drag reducer effectiveness testing further enhances the ability to maximise efficiency in industrial pipeline applications.

Flexibility and adaptability are at the core of our flow loop systems. Featuring variable speed pumps, in-line test spool sections, and removable test sections, these systems provide easy customisation for specific testing needs. This ensures that researchers can fine-tune experiments, explore a wide range of flow conditions, and gain valuable insights into pipeline performance under varying operational settings.

Moreover, our flow loop systems integrate advanced control mechanisms, allowing for precise management of flow variables. Whether simulating slow-moving fluids in laminar conditions or investigating turbulent flow in multiphase studies, these systems deliver high-fidelity data that researchers can rely on. Their durable construction and precise instrumentation make them ideal for academic, industrial, and commercial applications.

In an industry where accurate fluid analysis is critical, our flow loop systems offer the reliability, adaptability, and precision required for breakthrough research. Whether testing new materials, evaluating corrosion inhibitors, or optimising flow dynamics, these systems empower researchers to push the boundaries of innovation while maintaining rigorous safety and compliance standards.

"High-precision flow loop systems for single-phase and multiphase flow simulation,

corrosion analysis, and pipeline efficiency testing."

Product FAQ's

Flow loop systems are used to simulate and analyse fluid behaviour in pipelines, providing insights into flow patterns, corrosion effects, and efficiency improvements

Single-phase flow testing examines either liquid or gas flow independently, while multiphase flow systems study the interactions between liquid and gas in dynamic environments.

Our flow loop systems support corrosion flow analysis by replicating real-world conditions and allowing researchers to evaluate the impact of different flow regimes on material integrity.

Variable speed pumps allow precise control over flow rates, ensuring accurate and repeatable test conditions across different flow regimes.

Yes, with removable test sections and in-line test spool sections, our flow loop systems provide exceptional flexibility for various testing applications.

Applications

Application Note 1

Application Note 2

Application Note 3

Contact Us Today

We take great pleasure in assisting you and ensuring you get a prompt response to your questions

Live chat opening hours Mon – Fri 9:15 to 16:30 (UK Time)