Home » Products » Petroleum Testing » DR10

DR10 ITR Heater Tube Deposit Rater

The DR10 ITR deposit rater from AD Systems is an advanced interferometry-based device for precise measurement of deposit thickness on heater tubes in aviation fuel testing.

Product Overview

The DR10 is an innovative instrument designed for accurate measurement of jet fuel thermal oxidation deposit thickness on heater tubes, crucial in aviation turbine fuel testing.

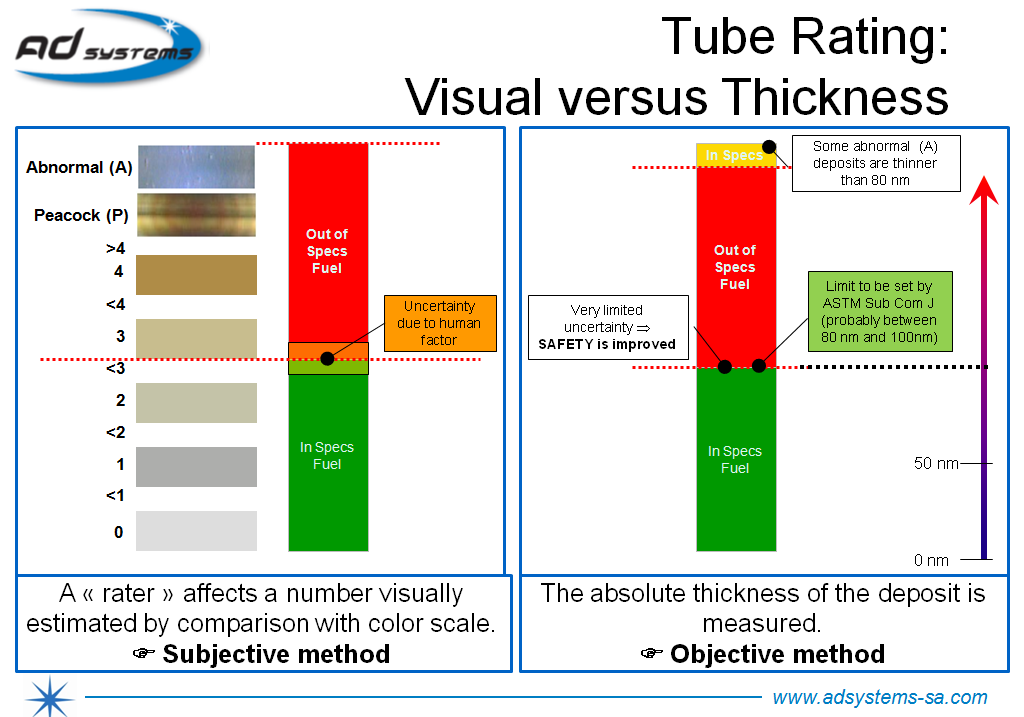

Utilising interferometry, the referee method outline in Annex A2 of ASTM D3241, it provides objective, precise, and reproducible measurements, eliminating the subjectivity associated with traditional visual assessments.

Compliant with ASTM D3241 standards, the DR10 delivers detailed 3D deposit profiles, enhancing the reliability of thermal oxidation stability evaluations.

Features & Benefits

Nanometer Precision - Accurate Deposit Measurements

Quick Analysis - Results in Under 15 Minutes

Intuitive Touchscreen - Simplified Operation

Space-Saving Design - Fits Any Lab Setting

Key applications

- Absolute Measurement Accuracy:

Provides precise deposit thickness measurements in nanometers, ensuring reliable data for fuel analysis. - Rapid Analysis:

Completes comprehensive deposit evaluations in under 15 minutes, optimising laboratory efficiency. Results can then be automatically reported with TO10 jet fuel thermal oxidation test data. - User-Friendly Interface:

Features an intuitive touchscreen for straightforward operation, reducing training requirements. - Compact and Robust Design:

Its small footprint and sturdy construction make it suitable for various laboratory environments. - Comprehensive Data Reporting:

Generates detailed 3D deposit distribution profiles, including standard spot values, average and maximum thicknesses, and total deposit volume

DR10 ITR Heater Tube Deposit Rater Product Video

About the DR10 ITR Heater Tube Deposit Rater

In the aviation industry, ensuring the thermal oxidation stability of aviation turbine fuels is paramount. Traditional methods of assessing deposit formation on heater tubes relied heavily on visual inspections, which were inherently subjective and prone to variability. This subjectivity often led to inconsistent evaluations, potentially compromising fuel quality assessments and subsequent engine performance. The need for a more objective, accurate, and reproducible method of measuring deposit thickness became evident, prompting the development of advanced instrumental techniques.

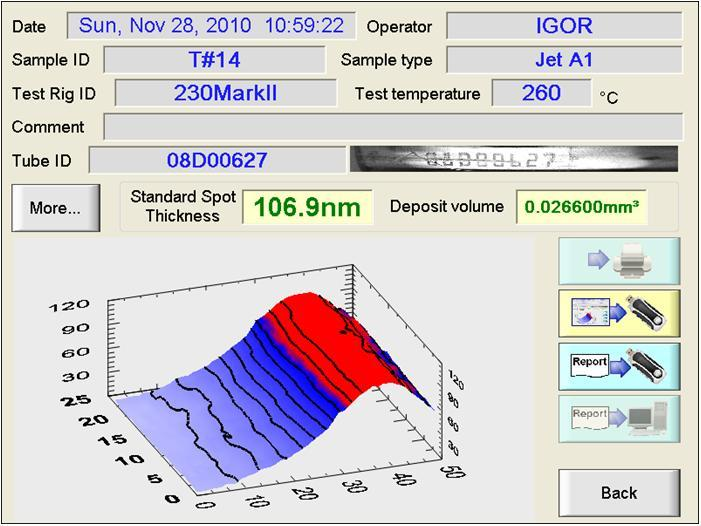

The DR10 addresses this critical need by utilising an interferometry-based (ITR) approach to deposit measurement, the referee method outlined in Annex 2 of ASTM D3241 and Annex C of IP323. By emitting specific light onto the heater tube surface and analysing the reflected interference patterns, the DR10 accurately determines deposit thickness down to the nanometer level. This method not only eliminates the subjectivity associated with visual assessments but also provides a comprehensive 3D profile of deposit distribution, offering deeper insights into fuel behaviour under thermal stress.

One of the standout features of the DR10 is its rapid analysis capability. Traditional methods could be time-consuming and required extensive operator expertise. In contrast, the DR10 completes a full deposit evaluation in less than 15 minutes, significantly enhancing laboratory throughput and efficiency. This speed does not come at the expense of accuracy; the instrument’s precise measurements ensure that fuel quality assessments are both quick and reliable.

The user experience has been a focal point in the design of the DR10. Equipped with an intuitive touchscreen interface, the instrument simplifies the testing process, allowing operators to input sample information and initiate scans with minimal training. The automated nature of the DR10 reduces the potential for human error, further enhancing the reliability of test results.

In terms of design, the DR10 boasts a compact and robust construction. Its small footprint ensures that it can be easily integrated into laboratories of varying sizes, while its sturdy build guarantees durability even in demanding environments. This combination of compactness and robustness makes the DR10 a versatile tool suitable for a range of applications, from research and development to routine quality control.

Data reporting is another area where the DR10 excels. Beyond providing standard measurements, the instrument generates detailed 3D profiles of deposit distribution on the heater tube surface. These reports include critical parameters such as the standard spot value, average and maximum deposit thicknesses, and total deposit volume. The heater tube rating data can then be compiled with the results from the TO10 jet fuel thermal oxidation test data

Such comprehensive data allows for a more thorough understanding of fuel performance and aids in the development of fuels with enhanced thermal stability.

In summary, the DR10 represents a significant advancement in the field of aviation fuel testing. By combining precision, speed, user-friendliness, and robust design, it effectively addresses the limitations of traditional deposit measurement methods. For professionals in the aviation industry seeking a reliable and efficient solution for heater tube deposit analysis, the DR10 offers an unparalleled blend of performance and convenience.

"The DR10 by AD Systems is a compact device that uses interferometry

to precisely measure deposit thickness in aviation fuel tests."

Product FAQ's

The DR10 measures deposit thicknesses ranging from 10 to 1,200 nanometers.

A comprehensive deposit evaluation is completed in under 15 minutes. Results can then be automatically combined with those recorded using the TO10 jet fuel thermal oxidation stability test rig

Yes, the DR10 complies with ASTM D3241, ASTM D1655, ASTM D7566, ISO 6249, and Def Stan 91-91 standards. It is the referee method outlined in Annex A2 of ASTM D3241.

The DR10 provides detailed 3D profiles of deposit distribution, including standard spot values, average and maximum thicknesses, and total deposit volume.

Yes, its compact and robust design makes it adaptable to a wide range of laboratory settings.

Yes, the DR10 and TO10 can be linked for automatic report generation, offering full traceability of all data for the sample.

Applications

Application Note 1

Application Note 2

Application Note 3

Contact Us Today

We take great pleasure in assisting you and ensuring you get a prompt response to your questions

Live chat opening hours Mon – Fri 9:15 to 16:30 (UK Time)