Home » Products » Petroleum Testing » CERT/SSRT Load Frames

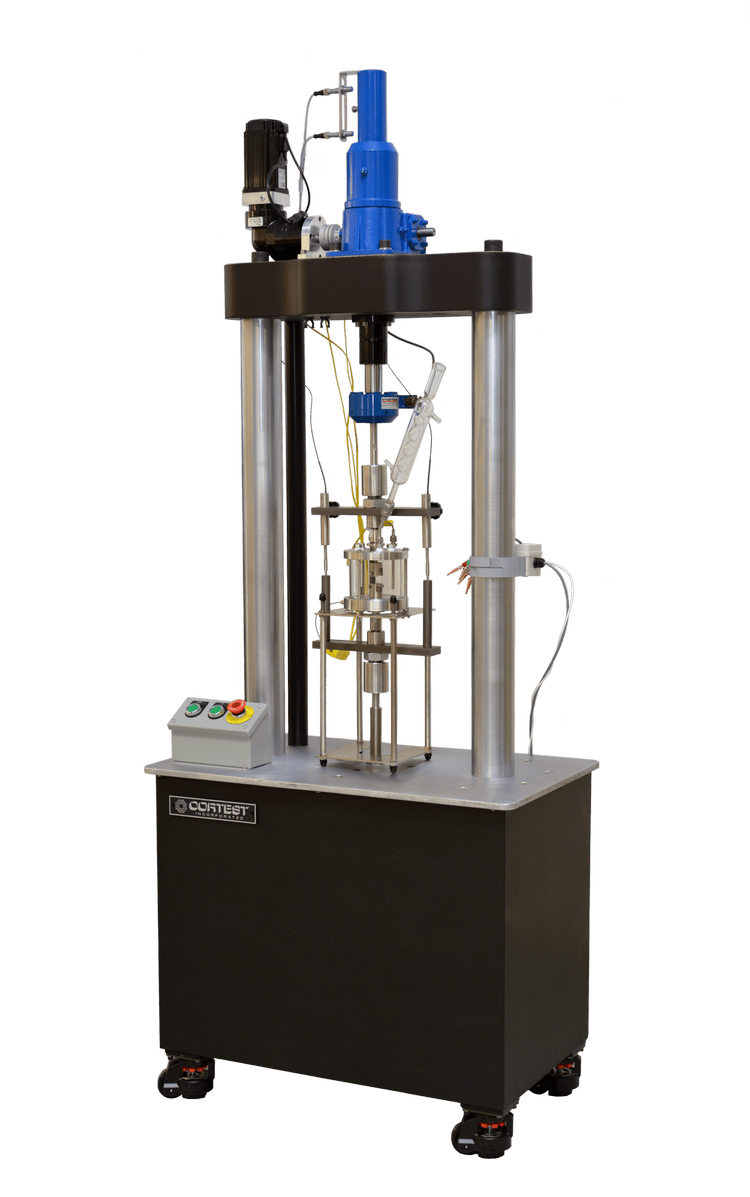

Advanced Slow Strain Rate Testing (SSRT) and CERT Load Frames

High-precision SSRT and CERT load frames for corrosion fatigue testing, HPHT applications, and NACE TM-0198 compliant experiments.

Product Overview

Our Slow Strain Rate Testing (SSRT) equipment and Constant Extension Rate Testing (CERT) systems provide advanced solutions for corrosion fatigue testing and high-temperature high-pressure (HPHT) load frame applications.

Engineered for precision, these systems incorporate stepper motor drives with gear reduction, Dual Linear Variable Differential Transformers (LVDTs) for displacement accuracy, and electrically isolated grip sets. The rigid 2-column and 4-column load frame construction ensures durability and stability during testing.

Featuring PC-controlled data acquisition systems and LabVIEW-based testing software, these load frames provide researchers and engineers with a reliable platform for evaluating material performance in extreme conditions. Designed to meet NACE TM-0198 compliance standards, our systems also support pull-through rod systems for autoclaves, enhancing testing capabilities in harsh environments.

Features & Benefits

Extreme Condition Testing: Supports HPHT environments with precision.

Corrosion Resistance Analysis: Ideal for evaluating material degradation.

Accurate Load Measurement: Ensures consistent and reliable force application.

Advanced Data Control: PC-based acquisition with LabVIEW integration.

Key applications

- Slow Strain Rate Testing (SSRT) Equipment: Ensures precise material deformation analysis.

- Constant Extension Rate Testing (CERT) Systems: Ideal for controlled corrosion studies.

- High Temperature High Pressure (HPHT) Load Frames: Supports extreme environmental testing.

- Corrosion Fatigue Testing Apparatus: Designed for long-term material durability studies.

- NACE TM-0198 Compliant Testing Equipment: Meets industry standards for corrosion evaluation.

- Pull-Through Rod Systems for Autoclaves: Enhances efficiency in high-pressure testing.

- Electrically Isolated Grip Sets: Prevents interference during electrochemical testing.

- Dual Linear Variable Differential Transformers (LVDTs): Enables precise displacement measurements.

- Stepper Motor Drive with Gear Reduction: Provides smooth and controlled movement.

- Precision Load Measurement Systems: Ensures accurate force application and data recording.

- Rigid 2-Column and 4-Column Load Frame Construction: Enhances stability for high-accuracy testing.

- PC-Controlled Data Acquisition Systems: Automates data collection for streamlined testing processes.

- LabVIEW-Based Testing Software: Customisable and user-friendly control interface.

- Pull-Through Autoclaves Meeting International Standards: Compatible with leading laboratory setups.

VD10 Automatic Video Distillation Analyser Product Video

About the CERT/SSRT Load Frames

Material durability and resistance to environmental stressors are critical factors in industries such as energy, aerospace, and automotive manufacturing. Corrosion fatigue and slow strain rate testing are vital methodologies for assessing material performance under simulated real-world conditions.

Our SSRT and CERT load frames address these challenges by providing controlled, high-precision testing environments that ensure reliable and reproducible results.

Traditional testing equipment often lacks the necessary precision and durability to simulate prolonged exposure to corrosive environments accurately.

Our load frames are engineered with high-temperature high-pressure (HPHT) capabilities, enabling researchers to subject materials to extreme stress while maintaining complete control over environmental variables. The integration of corrosion fatigue testing apparatus ensures that the materials’ endurance against cyclic stress and environmental factors can be comprehensively analysed.

Key to our system’s reliability is its stepper motor drive with gear reduction, which allows for ultra-smooth movement control, critical for slow strain rate testing. The dual linear variable differential transformers (LVDTs) enhance displacement measurement accuracy, ensuring that every micro-movement is precisely recorded. Electrically isolated grip sets prevent external interference during electrochemical testing, preserving data integrity.

Safety and compliance are also prioritised. Our load frames adhere to NACE TM-0198 standards, ensuring that the testing procedures align with international industry requirements.

The pull-through rod system for autoclaves allows seamless integration with high-pressure containment systems, further enhancing their applicability in material testing scenarios.

LabVIEW-based testing software powers the data acquisition system, offering user-friendly control and automation capabilities. Researchers can configure test parameters, monitor results in real-time, and generate detailed reports for further analysis. Additionally, our 2-column and 4-column load frame constructions provide the necessary rigidity and stability for high-precision testing, reducing variability and enhancing repeatability.

By investing in our SSRT and CERT systems, laboratories and research institutions gain access to cutting-edge technology that streamlines testing processes while delivering accurate, repeatable, and industry-compliant results.

"Advanced SSRT and CERT load frames for corrosion fatigue testing and HPHT applications.

NACE TM-0198 compliant with precision measurement systems."

Product FAQ's

SSRT is a technique used to evaluate material susceptibility to stress corrosion cracking by applying a slow, controlled strain rate to a specimen in a corrosive environment.

CERT applies a constant rate of extension rather than strain, making it particularly effective for evaluating ductility and corrosion resistance under tensile loading.

Industries such as oil & gas, aerospace, automotive, and materials science use corrosion fatigue testing to assess component longevity in harsh environments.

Dual LVDTs provide highly accurate, independent measurement of specimen elongation, ensuring precise monitoring of material deformation during testing.

Yes, our SSRT and CERT systems comply with NACE TM-0198, ensuring they meet industry-recognised testing requirements for corrosion and fatigue assessment.

Applications

Application Note 1

Application Note 2

Application Note 3

Contact Us Today

We take great pleasure in assisting you and ensuring you get a prompt response to your questions

Live chat opening hours Mon – Fri 9:15 to 16:30 (UK Time)