Home » Products » Petroleum Testing » Automatic Microscale Vapor Pressure Analyzer

Automatic Microscale Vapour Pressure Analyser

The Automatic Microscale Vapour Pressure Analyser is used to determine the ‘Total Vapour Pressure exerted in a vacuum for samples of volatile liquid petroleum products’. It conforms to the specifications of: ASTM D5191 and D6378.

Product Overview

The K24870 Automatic Microscale Vapour Pressure Analyser, is an automated instrument to determine Vapour Pressure of volatile petroleum products. Vapour pressure is a common test for fuels, specifically gasolines, as it is an important specification for transportation and storage of fuels. The two main methods run on this instrument are the ASTM D6378 and D5191.

ASTM D5191 is based on the mini method, developed in 1991, and requires only 1ml of sample. This is the dry vapour pressure equivalent, or DVPE.

ASTM D6378 uses the triple expansion method, developed in 1999 by Dr. Grabner. The K24870 automatically calculates the Vapour Pressure using this method which also requires a very small sample size of around 2mls.

The ability of the K24870 to automate these essential Vapour Pressure methods make it an ideal choice for the modern laboratory or testing facilities. In addition, the instrumentation is small, lightweight, and portable, allowing for vapour pressure testing to occur anywhere.

Features & Benefits

Ease of Use

Industrial 7-inch Colour Touch Screen

Small Footprint

Fuel Analysis

Fully Automatic

The K24870 has the following features:

- Fully Automatic – select the method and when complete the result will be displayed and stored

- Small sample volume required: 1ml of sample is required for each test plus 2.5 ml for each rinse to avoid contamination (3x rinse per cycle)

- Industrial 7-inch Colour Touch Screen User Interface with built-in test methods ensures ease of operation.

Flexible Software Capabilities

- Standard test methods are preprogrammed plus user-defined test programs can also be created

- Measurement of multiple temperature points in steps from 0.1°C and up to 100 points is optional

- Up to 1,000 results can be stored

The instrument has several interfaces:

- RS232 interface for connection to thermal printer

- USB interface for connection with mouse or storage device

- Internet (Ethernet) connection

K24870 Product Video

About the Automatic Microscale Vapour Pressure Analyser

There are various ASTM methods to determine the vapour pressure of volatile petroleum samples. The Reid method, described in ASTM D323, is the referee method and was published in 1930. It is referred to as Reid vapour pressure, or RVP. More recently newer methods have been developed which require smaller sample volumes and easier procedures.

ASTM D6378: is used to determine the vapour pressure exerted in vacuum by volatile, liquid petroleum products such as hydrocarbons, and hydrocarbon-oxygenate mixtures. This method is suitable for testing samples with boiling points above 0°C that exert a vapour pressure between 7 kPa and 150 kPa at 37.8°C at a vapour-to-liquid ratio of 4:1.

This method is based on the triple expansion method for vapour pressure determination which was developed by Dr. Grabner in 1999. It now serves as the new standard of vapour pressure testing in the industry. ASTM D6378 also provides correlative equations to calculate the RVPE and DVPE.

ASTM D5191: Is used to determine the total vapour pressure exerted in a vacuum by air-containing, volatile, liquid petroleum products, such as automotive spark-ignition fuels with or without oxygenates. This method is suitable for testing samples with boiling points above 0°C that exert a vapour pressure between 7 kPa and 130 kPa at 37.8°C at a vapour-to-liquid ratio of 4:1. This method is called the mini method as it only requires 1ml of sample, and was developed in 1991. ASTM D5191 is the dry vapour pressure equivalent, or DVPE.

The K24870 Microscale Vapour Pressure Analyser is based on the Triple-Expansion Principal. To perform a test the measured sample is injected into the temperature-controlled measuring chamber containing a piston.

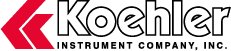

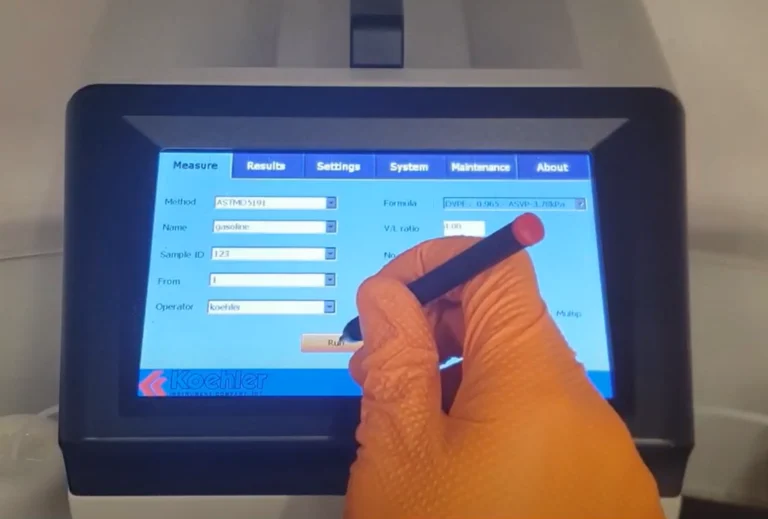

From the menu, the operator selects the test method, enters the sample name and presses the RUN button:

The sample chamber is sealed and the samples volume is expanded by X times in three steps. The total pressure is measured after every expansion step then the dissolved partial pressure of the air and dissolved partial pressure of air in the sample are calculated.

The temperature is increased to a certain value and the total pressure is measured at this temperature. By taking the difference of the total pressure after final expansion and the partial pressure from dissolved air, the vapour pressure of the sample is then calculated.

The result is clearly displayed on the screen and the test report can also be accessed in the results tab.

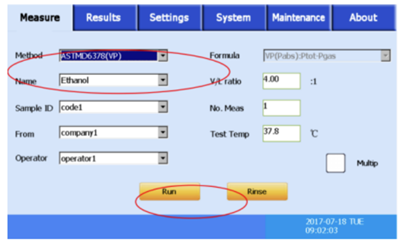

It is also possible to run experiments with Multi Point Temperature Measuring methods:

User defined methods are also possible by modifying a current method and saving with a different name.

The result is clearly displayed on the screen

Multi Point Temperature Measuring methods

Product Specifications

Feature | Specification |

Conforms to the specifications | ASTM D5191, D6378 |

Excellent Correlation to | ASTM D323, D4953; EN 13016-1; ISO 2007; IP 394; JIS K2258-2; SH/T 0794, SH/T 0769; GB/T 8017I; SN/T 2932 |

Temperature Range | 0 °C to 120 °C |

Temperature Stability | ± 0.1 °C |

Pressure Range | 0 kPa to 1000 kPa (0 psi to 145 psi) |

Pressure Resolution | 0.01 kPa |

Automated Calibration Routine | Yes |

Calibration Method | Fast & Easy On-Site Calibration |

Sample Volume | 1 mL (plus 3 x 2.5 mL rinse) |

Vapour / Liquid Ratio | 0.02:1 to 4:1 |

Interfaces | RS232, USB, Ethernet |

Up to 1000 results can be stored can be stored on the instrument and these results can be backed up onto a USB or exported to a LIMS system.

"The Koehler K24870 is an automatic vapour pressure analyser,

meeting ASTM standards, ideal for petroleum product testing

with its precision and minimal sample size."

Product FAQ's

The instrument requires less than 10mls sample, including 3 x rinse cycles between each sample.

The K24870 is an automated instrument, the operator simple places the sample in the cup, selects the method and enters the sample name then presses RUN. Results are automatically calculated and stored in the Results tab.

Correlative equations can be used to obtain a Reid vapour pressure equivalent (RVPE) and dry vapor pressure equivalent (DVPE) with the results from ASTM D6378.

Yes, it’s equipped for volatile hydrocarbons analysis.

Yes, it’s an essential tool for fuel analysis.

Applications

Application Note 1

Application Note 2

Application Note 3

Contact Us Today

We take great pleasure in assisting you and ensuring you get a prompt response to your questions

Live chat opening hours Mon – Fri 9:15 to 16:30 (UK Time)