Dublin Analytical Applications

A new way to test the low temperature mobility of lubricating grease

In Summary

Low temperature grease mobility testing measures how lubricants perform at reduced temperatures. It ensures machinery remains protected under cold start conditions and harsh environments.

Understanding Low Temperature Grease Mobility for Industrial Lubricants

Lubricating greases are a mixture of a base oil, additives and a thickening agent. These three components all contribute to a grease’s viscosity but, regardless of the composition, low temperatures will have a stiffening effect on grease. Lubricants tend to stiffen near their lower temperature limits, which has a deleterious impact on their lubricity. However, unless the grease is aged, the lubricant will typically return to full performance when the temperature is raised.

It’s essential for grease manufacturers to accurately determine their products’ behaviour at a range of temperatures, as too-viscous lubricants can cause severe mechanical issues. These can include local overheating, local lubricant starvation and wear debris scoring. As a result, grease analysis, including low temperature mobility testing, is a vital consideration for meeting grease production regulations.

What instrument can I use for grease mobility testing at low temperatures?

Low temperature grease mobility plays a key role in how lubricants perform in cold climates. If grease becomes too thick or sluggish at low temperatures, it may not flow properly, leaving moving parts unprotected.

As a result, equipment can experience higher wear, energy loss, or even failure.

Engineers measure grease mobility using standardised test methods. For example, ASTM D1092 measures apparent viscosity by rotating a rotor at constant speed inside a stator block. In addition, cone penetration testing is often used to measure how far a cone sinks into the grease under controlled conditions.

Together, these tests provide reliable insight into how grease will flow and lubricate machinery at low operating temperatures.

How does the Low Temperature Flow Tester (K95300) measure lubricating grease mobility?

The Koehler K95300 employs the Kesternich method and adheres to DIN 51805. For this test, the user fills the test nozzle with the grease sample, typically by repeatedly pressing the nozzle against the sample until a sufficient amount is inside. After the device has been cooled to the selected temperature, pressure is applied to the grease sample and increased every 30 seconds until the grease sample has been forced out of the nozzle.

The instrument uses a cascaded Peltier system to cool the test sleeve down to the desired temperature. When the system recognises a rapid pressure decrease, the system will store the maximum pressure value as the test result. This pressure value can be converted to reflect the viscosity of the grease sample at the desired temperature.

What sample size do I need to investigate grease mobility using the Low Temperature Flow Tester (K95300)?

The Kesternich test, employed by the Low Temperature Flow Tester, only requires a sample size of approximately 2 g. By contrast, the current low temperature grease testing standards, such as ASTM D1092, the US Steel Mobility and the Lincoln Ventmeter tests all require at least 220 g of sample to conduct the test. This brings obvious cost benefits, as less sample is consumed to obtain the information.

How repeatable are the grease mobility results obtained using the Low Temperature Flow Tester?

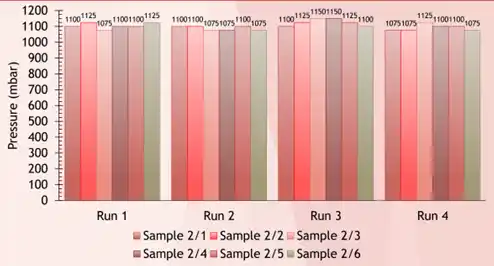

The maximum pressure values produced by the Kesternich method are highly repeatable, with a range of no more than 50 mbar and a maximum standard deviation of 2%. The 25 measurements for each run, displayed in Fig. 1, were collected at -20°C, 25 mbar steps and 30 second increase time.

Figure 1 – Maximum pressure values from a range of grease samples tested using K95300

What to Do Next?

Understanding low temperature grease mobility is essential for selecting the right lubricant and ensuring equipment reliability in cold environments. If you’d like to learn more about testing methods, review application notes, or speak with a product specialist, our team is here to help.

Contact us today for expert advice on grease testing solutions, recommended instruments, and industry best practices.

Page FAQ's

Low temperature grease mobility refers to how easily a grease can flow and lubricate moving parts when exposed to cold conditions. It directly impacts machinery reliability, wear, and energy efficiency in low-temperature environments.

In cold climates, grease can thicken and lose its ability to flow. Poor mobility can cause bearing failure, higher friction, or equipment downtime. Choosing a grease with the right mobility ensures consistent lubrication and reduced wear.

Common test methods include ASTM D1092, which measures apparent viscosity using a rotor and stator system, and cone penetration testing, which measures how far a cone sinks into the grease under controlled conditions.

Mobility is influenced by grease composition, base oil viscosity, thickener type, and the presence of additives. Temperature stability of the base oil is especially critical in determining performance in cold environments.

Industries such as automotive, aerospace, wind energy, and heavy machinery rely on grease mobility testing. Equipment in these sectors often operates in extreme conditions where reliable lubrication at low temperatures is essential.

Contact Us Today

We take great pleasure in assisting you and ensuring you get a prompt response to your questions

Live chat opening hours Mon – Fri 9:15 to 16:30 (UK Time)