Dublin Analytical Education

How Handheld NIR Devices are Transforming the Food Industry

In Summary

Handheld NIR devices offer rapid, non-destructive analysis for food quality control. They provide instant readings for moisture, fat, sugar and protein, helping processors improve consistency and reduce waste.

How Handheld NIR Devices Are Transforming the Food Industry

In an industry where quality, consistency, and safety are paramount, food companies are turning to cutting-edge technology to maintain high standards. One such innovation making waves is the handheld Near-Infrared (NIR) spectroscopy device.

Once limited to laboratory settings, NIR technology is now available in portable, easy-to-use devices that allow food manufacturers to perform real-time analysis and make data-driven decisions on the spot.

Enhancing Quality Control and Assurance

Handheld NIR devices enable food companies to quickly assess key quality attributes such as moisture, fat, protein, and carbohydrate content in raw materials and finished products. This rapid testing capability ensures that ingredients meet specifications before entering production lines, reducing the risk of costly rework or recalls.

For example, dairy producers can instantly check the fat and protein content of milk, cheese, and yogurt, ensuring that products maintain consistent taste and texture. Similarly, meat processors can analyse fat-to-protein ratios in cuts of beef or pork, ensuring compliance with labelling requirements and quality standards.

Wireless Analysis

Seamless Material Testing

Rugged Design

IP65 and IP67 Rated

Versatile Applications

From Pharmaceuticals to Food

Boosting Efficiency in Production Lines

Traditionally, food companies relied on time-consuming laboratory tests that could delay production. Handheld NIR devices streamline operations by providing immediate insights, allowing for on-the-spot adjustments to processing parameters. This capability helps manufacturers optimize ingredient usage, reduce waste, and improve overall efficiency.

In the bakery industry, for example, moisture content is a critical factor in determining the texture and shelf life of products. By using a handheld NIR device, bakery manufacturers can fine-tune drying and baking processes in real time, preventing under- or over-drying that could compromise product quality.

Ensuring Regulatory Compliance and Food Safety

Food safety regulations continue to tighten worldwide, and handheld NIR devices provide a powerful tool for ensuring compliance. These devices can help food companies verify that their products meet regulatory standards regarding ingredient composition and labelling claims.

Additionally, NIR spectroscopy can assist in detecting food adulteration and contamination. For instance, the technology can identify whether olive oil has been diluted with lower-quality substitutes or if honey has been mixed with high-fructose corn syrup. This level of analysis helps companies protect brand integrity and consumer trust.

Reducing Costs and Minimizing Waste

By enabling real-time quality control, handheld NIR devices help food companies minimize waste and optimize raw material usage.

Whether adjusting formulations to meet specifications or detecting inconsistencies before full-scale production, these devices help manufacturers reduce financial losses associated with off-spec batches and inefficient processes.

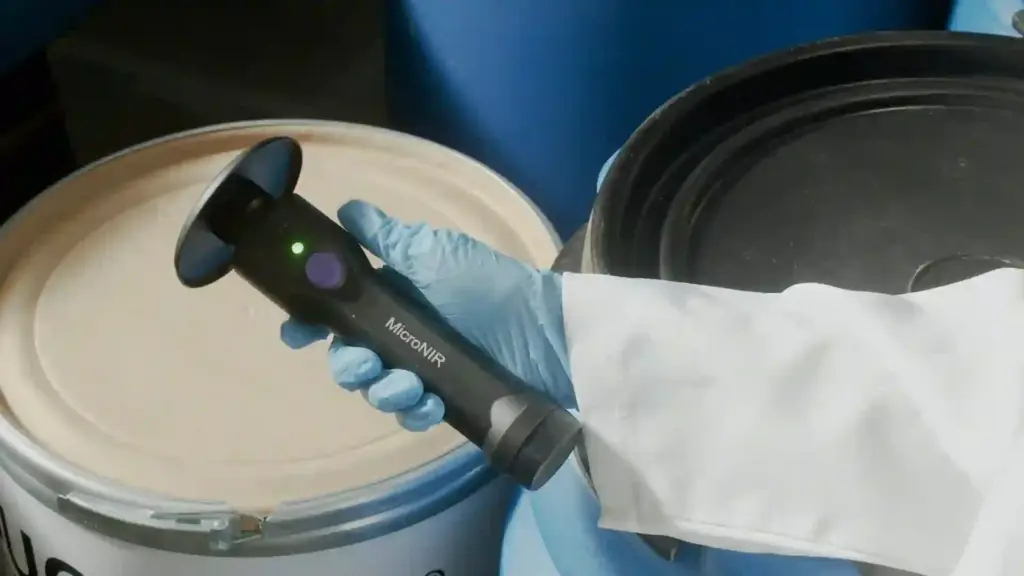

The MicroNIR OnSite-W

The MicroNIR OnSite-W offers real-time, non-destructive NIR material analysis in a compact, rugged, and wireless design.

Boosting Efficiency in Production Lines

Traditionally, food companies relied on time-consuming laboratory tests that could delay production. Handheld NIR devices streamline operations by providing immediate insights, allowing for on-the-spot adjustments to processing parameters. This capability helps manufacturers optimize ingredient usage, reduce waste, and improve overall efficiency.

In the bakery industry, for example, moisture content is a critical factor in determining the texture and shelf life of products. By using a handheld NIR device, bakery manufacturers can fine-tune drying and baking processes in real time, preventing under- or over-drying that could compromise product quality.

Conclusion

For food manufacturers looking to streamline operations, improve quality assurance, and maintain regulatory compliance, investing in handheld NIR technology is a game-changer.

As the industry moves toward more data-driven and efficient production methods, these compact devices are proving to be invaluable assets in ensuring food quality and safety at every stage of the supply chain.

What to do next?

If you’d like to learn more about handheld NIR devices—whether you’re seeking technical specifications, practical implementation advice, or wish to speak with a member of our expert team—please get in touch using the contact details below. We’re here to help you unlock the full potential of this transformative technology and ensure it aligns with your production and quality control goals.

Page FAQ's

Moisture, fat, sugar, protein and other key quality indicators.

They provide immediate results without lab analysis.

Yes. Portable NIR analysers suitable for factory and field use.

Contact Us Today

We take great pleasure in assisting you and ensuring you get a prompt response to your questions

Live chat opening hours Mon – Fri 9:15 to 16:30 (UK Time)