Dublin Analytical Applications

SEM in FMEA of metallic materials

In Summary

SEM imaging supports Failure Mode and Effects Analysis by revealing microstructural defects in metallic materials. It helps engineers identify root causes of cracking, corrosion and fatigue. Dublin Analytical supplies a range of SEM solutions for industrial inspection.

What Is FMEA in Materials Science?

Failure Mode and Effects Analysis (FMEA) is a structured approach used to identify and evaluate potential points of failure within a material, process, or system. It allows engineers and researchers to assess how and why a material might fail under certain conditions.

FMEA is especially valuable in industries where material reliability is critical, such as aerospace, automotive, and manufacturing. By analysing possible failure modes, teams can take preventive actions before issues occur. As a result, FMEA supports product safety, durability, and performance.

In the context of metallic materials, FMEA focuses on understanding how metals behave under stress, fatigue, corrosion, or other environmental influences. However, identifying the exact cause of failure can be challenging without detailed imaging and analysis tools.

Why Use SEM in Failure Analysis?

Scanning Electron Microscopy (SEM) plays a vital role in supporting FMEA. It provides high-resolution imaging of a material’s surface, allowing engineers to examine cracks, fractures, wear patterns, and other microscopic features that are not visible to the naked eye.

Unlike traditional optical microscopy, SEM offers greater depth of field and magnification. Therefore, it becomes much easier to pinpoint the root cause of failure in metallic samples. For example, SEM can reveal if a crack was caused by fatigue, corrosion, or manufacturing defects.

In addition to visual analysis, SEM can be paired with Energy Dispersive X-ray Spectroscopy (EDS) to identify the chemical composition of materials. This further enhances the ability to detect impurities or inconsistencies that may have contributed to failure.

How can SEM be used in FMEA?

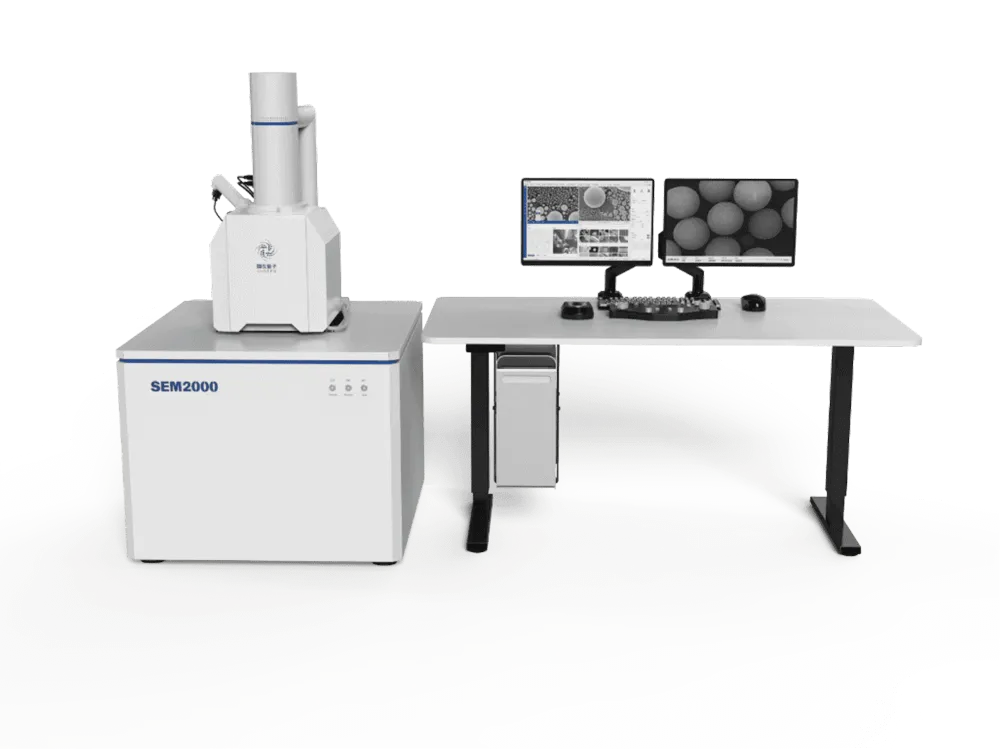

Using a scanning electron microscope is helpful for comprehensive FMEA.

When using SEM for failure analysis, the analytical method involves four main steps.

1. Sample preparation

Prepare metallic material samples for SEM analysis by cleaning and polishing them to enhance visibility under the microscope. Additionally, consider coating the samples for improved imaging quality.

2. Adjusting SEM parameters

Refine SEM parameters, including accelerating voltage, beam current and working distance to ensure optimal imaging and precise examination of metallic samples.

3. Image capture and analysis

Initiate the SEM to scan and capture high-resolution images of the metallic material surfaces. Use the SEM software for detailed analysis, examining microstructural features, surface defects and fracture patterns.

4. Microstructural examination

Examine and analyse surface characteristics, including grain boundaries, cracks and inclusions. Investigating surface defects is instrumental in understanding failure mechanisms.

How is FMEA applied across different industries?

FMEA is applied across various industries such as aerospace, automotive, manufacturing and more. SEM plays a crucial role by enabling detailed analysis and identification of failure causes, ensuring safety, quality, and reliability in each sector’s specific applications.

Aerospace and automotive

SEM helps ensure safety and efficiency in the aerospace and automotive sectors by identifying the underlying causes of failures. For example, SEM analysis detects critical issues such as microfractures or stress conditions in turbine blades, ensuring the continued safe operation of aircraft. In the automotive industry, SEM aids identification of fatigue-related cracks in engine components, enabling timely maintenance to prevent catastrophic failures.

Manufacturing and metallurgy

In manufacturing, SEM assists in detecting defects in critical components, such as microstructural anomalies in welds or casting imperfections. For instance, SEM analysis in metallurgical processes can pinpoint material inclusions that might affect steel quality, ensuring the production of high-performance materials. Furthermore, SEM aids in flaw identification, such as highlighting porosity in manufactured parts, so that manufacturers can take preventative measures against quality issues.

Biomedical engineering

In the biomedical engineering sector, engineers conducting FMEA employ SEM to inspect medical implants for defects or structural irregularities, establishing their integrity and reliability. In orthopaedic implants, SEM is helpful for identifying corrosion, ensuring the safety and longevity of implants. Similarly, SEM analysis of pacemaker components aids in detecting material fatigue, leading to iterative improvements in implant design to enhance reliability and ensure patient well-being.

Energy and construction

SEM-based FMEA supports the energy sector during the investigation of metallic materials in pipelines, helping to detect corrosion or stress-related fractures. For instance, SEM aids in identifying microfractures at critical weld points, effectively preventing gas leaks in pipelines. Similarly, in the construction industry, SEM proves instrumental in identifying structural defects in building materials. This application ensures the structural integrity of buildings, safeguarding against issues like steel fatigue and potential failures.

How do I interpret SEM results?

Interpreting SEM results in failure analysis involves a series of steps for comprehensive assessment.

1. Surface inspection and morphology analysis

Conduct a detailed examination of surface morphology and structure to identify anomalies, fractures or irregularities that could contribute to failure mechanisms.

2. Quantitative assessment

Conduct a detailed examination of surface morphology and structure to identify anomalies, fractures or irregularities that could contribute to failure mechanisms.

3. Elemental composition

Use X-ray spectroscopy to determine the elemental composition of the sample. This step allows for the identification impurities, variations or material inconsistencies that may impact failure.

4. Surface characterisation

Assess the sample’s surface characteristics, including texture, roughness and topographical irregularities, to gain insights into structural integrity and surface properties related to failure.

5. Defect identification

Examine the sample to identify microstructural defects, discontinuities or irregularities contributing to material failure mechanisms.

What to Do Next?

Upon extracting insights from SEM analysis, the next phase involves implementing strategic adjustments in material design or production methodologies based on the findings.

For tailored solutions or comprehensive further analysis, we highly recommend consulting with SEM experts. This allows for a collaborative approach to deciphering SEM data and devising effective strategies for enhancing material integrity or refining production processes.

Reach out to the team below to see how Dublin Analytical’s range of SEMs can work for your application.

Page FAQ's

The scanning electron microscope (SEM) plays a critical role in FMEA by providing high-resolution imaging and compositional analysis. It enables you to identify microstructural defects such as cracks, inclusions, porosity, and fracture surfaces, all of which may contribute to failure. With SEM data, you can more precisely determine root-causes of failure modes and improve material design, processing, or maintenance strategies.

Sample preparation is essential for reliable SEM results. First, the surface must be cleaned to remove contaminants that could obscure defects. Then polish to a smooth finish for clear imaging. Depending on the material and desired contrast, you may need to coat samples (e.g. with conductive coatings) to prevent charging. Good preparation makes features like grain boundaries, inclusions, and micro-cracks more visible.

Many industries rely on SEM-assisted FMEA to ensure quality, safety, and reliability. Key sectors include:

Aerospace (for analysing turbine blades, microfractures)

Scimed

Automotive (for fatigue cracks, wear in engine components)

Scimed

Manufacturing & metallurgy (welds, castings, material inclusions)

Scimed

Biomedical engineering (implants, orthopaedic devices, corrosion detection)

Scimed

Energy & construction (pipeline weld integrity, steel fatigue in structures)

To get meaningful SEM data for FMEA, you need to control several instrument parameters:

Accelerating voltage – affects electron penetration and resolution. Scimed

Beam current – influences signal strength vs damage or charging. Scimed

Working distance – impacts depth of field and image clarity. Scimed

Magnification & resolution settings – essential for observing features of interest.

Detector type (secondary electron, backscatter etc.) – for contrast of topography vs composition.

Surface inspection and morphology analysis to spot irregularities. Scimed

Quantitative assessment of defect size, density, distribution.

Elemental/compositional analysis (e.g. via X-ray spectroscopy) to detect impurities or variations. Scimed

Surface characterisation (texture, roughness, topography) to understand failure risk. Scimed

Defect identification (grain boundary issues, inclusions, micro-cracks) to establish probable failure mechanisms.

Contact Us Today

We take great pleasure in assisting you and ensuring you get a prompt response to your questions

Live chat opening hours Mon – Fri 9:15 to 16:30 (UK Time)