Dublin Analytical Education

A Practical Guide to Testing AOX in Wastewater/Effluent Samples

Introduction

- AOX (adsorbable organic halogen) testing is now a requirement for wastewater/effluent discharge permits in the UK. Samples typically require daily testing, meaning that testing on-site with a fast turnaround is preferred compared to subcontracting to a third-party laboratory.

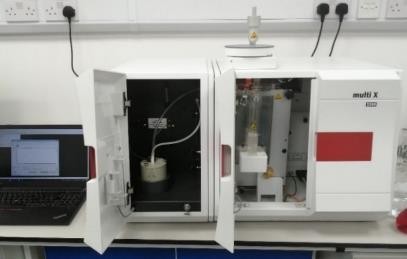

- In practice, the method can be implemented with the APUsim (Analytik Jena) for sample preparation and the Multi X 2500 for combustion and automated micro‑coulometric titration—both distributed in the UK by Dublin Analytical. The sections below outline the exact steps, reagent volumes and run times you can follow immediately on site.

- Find out more about AOX testing below;

Why is AOX testing required?

AOX testing supports compliance with UK wastewater/effluent discharge permits. Because monitoring is often required daily, a rapid on-site workflow is advantageous. This guide outlines a practical procedure aligned to ISO/FDIS 9562.

Quick facts:

- Standard: ISO/FDIS 9562 – Water quality – Determination of adsorbable organic halogens (AOX).

- Typical discharge limit: < 1 mg/L.

- Wastewater sample collection

- Removal of excess chloride and/or dissolved carbon (if required)

- Adsorption onto activated carbon tubes

- Measurement of AOX content of the tubes

How do I collect samples for AOX testing?

Collect at least 250 ml of the wastewater sample in a suitable plastic or glass container and seal. The sample should be acidified to pH<2 through the addition of about 0.2% concentrated nitric acid as soon as possible. Addition of 10 ml/L sodium sulphite may also be required if the sample contains highly active oxidizing agents. The sample should be prepared as-soon-as-possible after collection using the APUsim.

How do I prepare samples for AOX with high chloride or dissolved carbon content?

Most wastewater and effluent samples have high dissolved inorganic chlorine contents (Cl– 1-100 g/L) and/or high total dissolved carbon (DOC 10-1000 mg/L).

In this case an additional extraction step is needed, as chloride and carbon can interfere with adsorption to the activated carbon column.

This is performed using the APUsim from Analytik Jena and exclusively supplied by Dublin Analytical in the UK.

Prime an SPE cartridge (styrene divinyl benzene copolymerized resin) with 5 ml methanol (using a 5 ml disposable plastic syringe) and attach beneath the 100 ml syringe.

Take at least 10 ml of sample (or 5 ml of SPE eluate), accurately measured, and dispense into the 100 ml syringe tube.

Add 5 ml of sodium nitrate stock solution (NaNO3 @ 0.2 mol/L) and 0.2 mol concentrated nitric acid. Dilute to 100 ml.

Press the start button on the APUsim. The sample is pumped through the activated carbon columns at a rate of 3 ml/min taking 45 minutes (including an automated 25 ml rinse)

Elute the SPE column back into the 100 ml APU syringe, using 5 ml of methanol. Treat this eluent in the same way as wastewater with low chloride and DOC, as described below.

How do I adsorb samples onto activated carbon tubes?

AOX in the wastewater sample is adsorbed onto a carbon column; inorganic halogens are not adsorbed (for samples with high chloride or DOC content, see SPE procedure described above).

Remove the plunger for the 100 mL syringe of the APUsim.

Take at least 10 mL of sample, accurately measured, and dispense into the 100 mL syringe tube.

Add 5 mL sodium nitrate stock solution (NaNO₃ @ 0.2 mol/L) and 0.2 mol concentrated nitric acid.

Dilute to 100 mL and replace the plunger.

Assemble the activated carbon tubes into the extraction column with two in-line tubes (duplex).

The majority of the AOX is adsorbed onto the first carbon tube.

If this is not the case, the sample may need SPE pre-extraction (see above).

The second tube acts as a back up to ensure complete adsorption.

Attach the column beneath the syringe and press the Go button on the APUsim.

The sample is pumped through the carbon columns at 3 mL/min for ~45 minutes (including an automated 25 mL rinse).

For high throughput laboratories: a fully automated sample preparation system (SPE and activated carbon) is provided by the APU 28 from Analytik Jena, exclusively supplied in the UK by Dublin Analytical.

In this video you will see:

How to set up the APUsim for AOX sample preparation.

Loading a wastewater/effluent sample into the 100 mL syringe.

Automated pumping through activated carbon tubes at 3 mL/min with a 25 mL rinse.

The use of duplicate carbon tubes (duplex) to ensure complete AOX capture.

How the system simplifies preparation in line with ISO/FDIS 9562.

How do I measure the AOX content of the column?

As only the AOX was retained by the column, and inorganic halogens were not absorbed, we can measure the AOX content of the column by determining the total halogen (X = Cl + Br + I) content (a specific organic halogen detector is not required).

1. Standard & Instrument

AOX determination follows ISO/FDIS 9562, treating AOX as the sum of organically bound halogens in the sample.

Furnace combustion at 950 °C under an oxygen flow converts organo-halogens to halides/hydrogen halides for quantitative capture.

The Multi X 2500 (Analytik Jena) combines the high-temperature furnace with automated micro-coulometric titration in one workflow.

In the titration cell, an all-in-one silver electrode precipitates halides; the current is proportional to silver delivery, so no external calibration is required.

AOX is calculated from the integrated area/charge of the titration curve, giving a direct, linear readout of total halogen content.

System is exclusively distributed in the UK by Dublin Analytical and is suitable for routine compliance monitoring alongside duplex carbon tube preparation.

2. Sample Introduction to the Furnace

Remove the two activated carbon tubes from the extraction column.

Load them into the autosampler and drop into the 950 °C combustion vessel under oxygen (or introduce manually with clean tweezers).

Run order: primary tube first, then backup; verify the method file, furnace setpoint, and O₂ flow.

Manual introduction: briefly open the inlet, seat the tube fully, and close promptly to maintain temperature.

Carryover control: include blanks/conditioning steps after high-AOX matrices as specified by your method.

Safety: wear PPE; avoid touching the carbon bed and hot surfaces; dispose of spent tubes according to lab procedures.

3. Gas Handling & Transfer

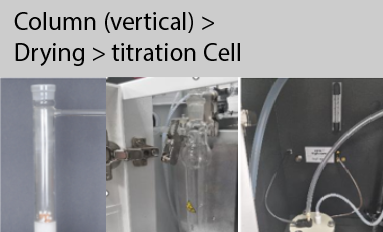

Combustion releases the halogen, which is swept from the furnace by the oxygen carrier stream and directed—via heated, inert transfer lines—through a drying trap and into the titration cell.

The transfer path is designed to prevent condensation or adsorption losses, ensuring the liberated halogens (or hydrogen halides) reach the cell quantitatively.

The drying trap removes moisture to protect the titration electrolyte and maintain a stable baseline. Any particulates generated during combustion are retained before the cell.

A steady, leak-free flow is important for reproducibility: check fittings, flow settings, and trap condition regularly to minimise memory effects and drift.

The gas stream enters the titration cell continuously so that the subsequent micro-coulometric titration reflects the full halogen load released during combustion.

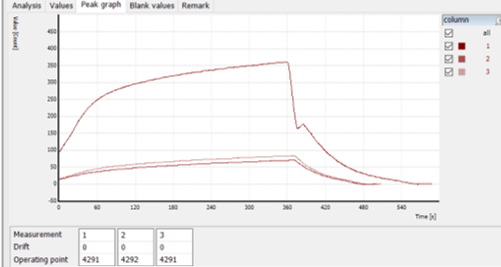

4. Micro-Coulometric Titration & Quantification

In the titration cell, released halides are trapped in the electrolyte for immediate measurement.

An all-in-one silver electrode precipitates halides as AgX during titration.

The current is proportional to silver delivery, so no external calibration is required.

AOX is computed from the integrated area/charge of the titration curve.

Maintain baseline stability with fresh electrolyte and periodic blanks.

Report results as mg/L AOX, applying any dilution factors used upstream.

5. Capture Efficiency & Method Assurance

Most AOX is adsorbed on Tube 1; Tube 2 serves as a backup safeguard.

If Tube 2 shows notable signal, implement SPE pre-extraction for that matrix.

For development, add a third tube and compare to a blank to confirm completeness.

Use duplicates and control standards (e.g., 4-chlorophenol) to verify recovery.

Set acceptance criteria for replicate agreement and spike recoveries.

Document tube IDs, lot numbers, and any method deviations for traceability.

6. Working Range & Sample Loading

Typical working range: 0.1–10 mg/L AOX for a 10 mL sample on Multi X 2500.

Extend range by dilution or adjusting the loaded volume per method guidance.

Avoid cell overload; very high AOX matrices may require greater dilution.

High chloride/DOC samples benefit from SPE pre-extraction to improve capture.

Autosampler supports routine throughput with consistent furnace/titration cycles.

Always include dilution factors and blank corrections in reported results.

How do I confirm the AOX measurement is accurate?

1. Accuracy Check Method

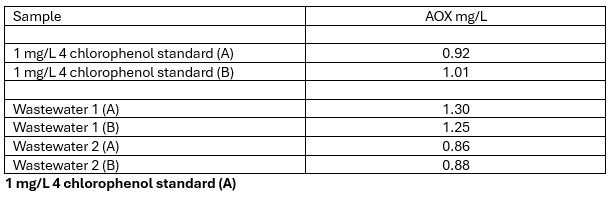

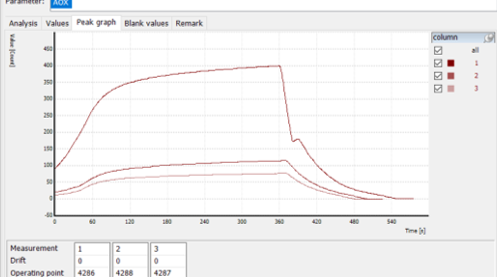

- The accuracy of measurement is determined by adsorbing and measuring a standard 4-chlorophenol solution using the APUsim and Multi X 2500 as described above. This is compared to the measurement of some real wastewater/effluent samples below.

2. Results Summary

One wastewater gave a result below the 1 mg/L limit and one just above, requiring action before discharge. Testing was performed in duplicate.

AOF/PFAS: Can I test for them?

- Can I also test samples for adsorbable organic fluorine (AOF) and PFAS? Yes. There is a similar sum parameter, AOF, for testing total fluorinated organic compounds; this is an accepted method for approximating total PFAS.

How it’s done (Prep & Detection)

- The sample preparation is very similar, using the APUsim and activated charcoal columns. The detection is different and can be achieved using the ICprep from Analytik Jena (exclusively distributed in the UK by Dublin Analytical), with detection by Ion Chromatography or molecular continuum-source AAS.

Conclusion: Putting AOX (and AOF/PFAS) into Practice

On-site AOX testing—using APUsim for preparation and Multi X 2500 for combustion and micro-coulometric titration—gives fast, defensible results against typical discharge limits and aligns with ISO/FDIS 9562. For matrices with high chloride/DOC, SPE pre-extraction improves capture and data quality, while duplicate standards and wastewater samples help confirm accuracy. If you also need a total fluorine proxy for PFAS, adopt AOF with similar preparation and dedicated detection.

What to do next?

At Dublin Analytical, we offer a full range of advanced SEM systems tailored for battery materials research and quality control, including the CIQTEK SEM5000X, specifically designed for high-resolution low-voltage imaging, elemental mapping, and automated workflows ideal for industry operators.

If you’re ready to enhance your battery research or production process, get in touch with Dublin Analytical to discover the SEM solution best suited to your application.

Contact Us Today

We take great pleasure in assisting you and ensuring you get a prompt response to your questions

Live chat opening hours Mon – Fri 9:15 to 16:30 (UK Time)