Home » Products » Petroleum Testing » AD Systems Automated Products for Fuels and Lubricants

AD Systems Automated Products for Fuels and Lubricants

AD Systems manufacture a range of automated instruments for evaluating physical properties of fuels and lubricants, specialising in the design and manufacturing of automated instruments for petrochemical testing.

Product Overview

AD Systems customers include oil refineries, commercial laboratories, fuel distributors, storage terminals and blenders, lubricant plants and Oil Condition Monitoring labs, academia and industry research labs, marine, aviation companies and military.

They are active members of many of the standardisation bodies such as: ASTM, Energy Institute, ISO and BNPé. They also work with governmental agencies and research departments of petroleum companies to develop prototypes which are then developed and manufactured as products at their site in France.

AD Systems Automated Product Videos

Playlist

1:13

5:24

4:07

2:33

About the AD Systems Automated Products

AD Systems manufactures the below products:

- TO10 – JFTOT for Thermal Oxidation of Aviation Fuels and DR10 ITR Heater Tube Deposit Rater: ASTM D3241, IP 323, ISO 6249,ASTM D1655, D7566, D4054, DEF STAN 91-091

- SP20 – Automated Smoke Point Tester: ASTM D1322, D1655, IP 598, Def Stan 91-91

- VD10 – Automated Atmospheric Distillation of Fuels and Solvents: ASTM D86, D850, D1078: ISO 3405, ISO 918, ISO 4626, IP123, IP195, JIS K2254, and other methods

- CB10 – Automated Corrosion Bath and CT10 Corrosion Rater: ASTM D665, D4378, NACE TM0172, IP 135, ISO 7120, GOST 19199, JIS K2510: ASTM D665, D7548 NACE TM0172 IP 135 ISO 7120 JIS K2510 GOST 19199

- DT100DL – Dispersancy of In-Service Engine Oils Oil Conditions Monitoring: ASTM D7899

- ST10 – On-Site Residual Fuel Compatibility Tester: ASTM D4740 ISO PAS 23263 CIMAC guidelines

- SV10 Automated S Value – Intrinsic Stability of Asphaltenes: ASTM D7157 ISO PAS 23263 CIMAC guidelines.

SP20 Automated Smoke Point Tester

ASTM D1322, D1655, IP 598, Def Stan 91-91

The automation of the smoke point test introduced by AD Systems greatly improved the precision of this test compared with the manual method, and consequently has become the referee test method in jet fuels specifications.

VD10 Atmospheric distillation of Fuels and Solvents

Using Innovative Video Distillation.

ASTM D86, D850, D1078: ISO 3405, ISO 918, ISO 4626, IP123, IP195, JIS K2254, and other methods.

With no need for programming or optimisation, the VD10 performs the perfect distillation test from the first sample, even for unknown and difficult samples such as biofuels.

TO10 Thermal Oxidation Stability of Aviation Fuels

Oxidation Stability Test Rig for JFTOT ASTM D3241, IP 323, ISO 6249, ASTM D1655, D7566, D4054, DEF STAN 91-091

The TO10 offers perfect control of sample flowrate, volume and pressure, combined with unparalleled precision of heater tube temperature profile control. A dedicated gauge allows easy and perfect tube positioning and no tools are required to assemble the test. With its fast cooling, the TO10 increases the lab productivity.

The instrument provides full traceability of the test run and can be coupled with the referee automatic tube rater, ITR (DR10), which can be linked to TO10 for automatic data transmission.

DR10 ITR Heater Tube Deposit Rater

The DR10 test report provides a 3-D profile of the deposit distribution on the tube surface. The software automatically detects and reports the Standard Spot value as defined in ASTM D3241. The average and the maximum thickness deposit values, as well as the calculated total deposit volume are reported.

The TO10 also has a specific feature to perform breakpoint determination as per Annex 2 of ASTM D3241(DR10 is required).

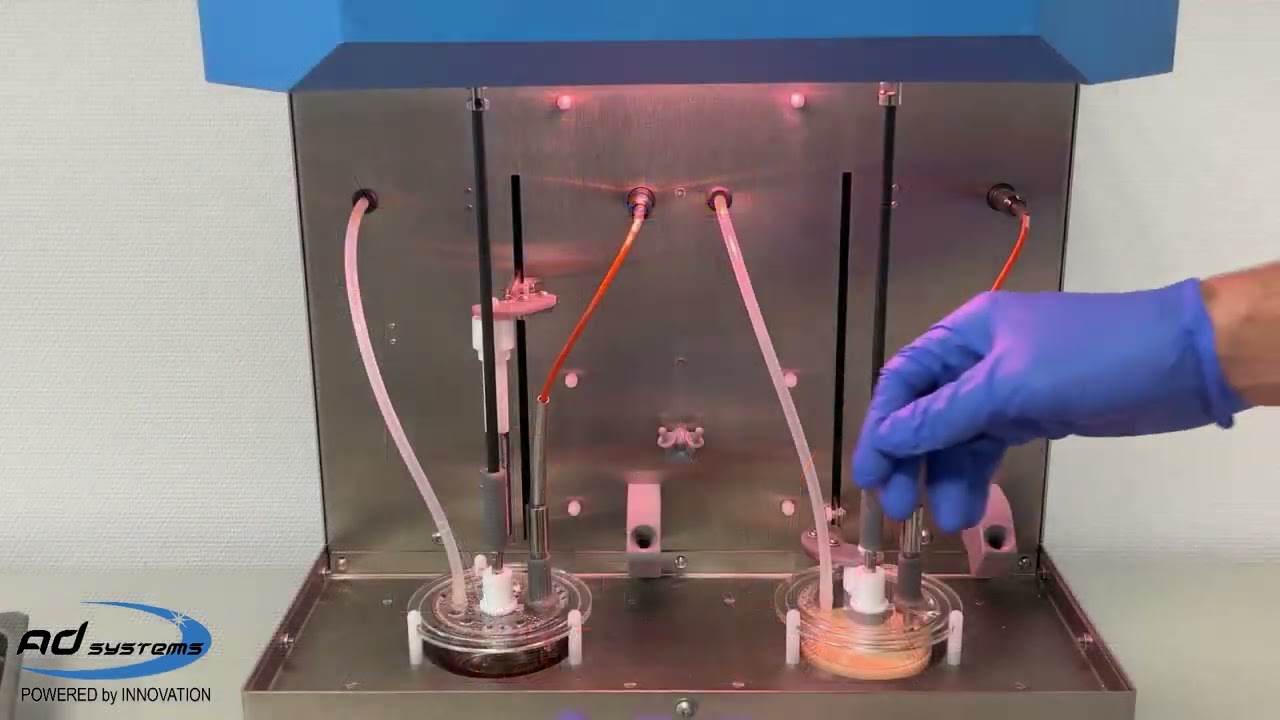

CB10 Automated Corrosion Bath

For testing the corrosion properties of fuels, mineral oils and pipeline cargoes.

ASTM D665, D4378, NACE TM0172, IP 135, ISO 7120, GOST 19199, JIS K2510

With the CB10 the whole test preparation is simplified and two tests can be run unattended simultaneously and independently. All the parameters such as test timing, water injection volume, temperature and specimen insertion are precisely controlled. The dry bath combined with the metal temperature probe make the CB10 robust and reliable in operation. With a complete set of accessories and pre-programmed or user defined methods, CB10 is suitable for any type of application.

CT10 Corrosion Rater

ASTM D665, D7548 NACE TM0172 IP 135 ISO 7120 JIS K2510 GOST 19199

After the test the rating can be measured using the CT10 Corrosion Rater which automatically calculates the exact percentage of the corroded area based on a homogeneous lighting source, CCD camera, specimen rotation system, and specially designed application software.

Using the CT10 significantly improves repeatability and reproducibility of results.

Engine Lubricant and Oil Condition Monitoring

DT100DL Dispersancy

In-Service Engine Oils Oil Conditions Monitoring ASTM D7899

The DT100 DL is a unique and easy to use instrument able to simultaneously quantify dispersancy and soot content and is ideal for trend analysis in OCM programs and diagnosis on diesel engines.

Applications

- Oil Conditioning Monitoring (OCM)

- Oil testing laboratories

- Engine test laboratories

- Fleet maintenance

- Construction or Mining sites

- On-board Ship

- Lubricant Research and Development

Fuel Compatibility Testing

ST10 On-Site Residual Fuel Compatibility Tester

Methods: ASTM D4740 ISO PAS 23263 CIMAC guidelines

The ST10 is a portable, on-site fully automated instrument for testing the compatibility and cleanliness of residual fuel oil and distillate according to the ASTM D4740 spot test.

The ST10 is a complete and automated system which is self-contained in a carrying case. It is designed for both on-board use on ships to test for compatibility of marine fuels and laboratory use.

- Uses the standard test method used by conventional laboratories.

- Fully automated so no training or analytical knowledge is required

- Removes subjectivity

- Prevent sludge deposits, failure of fuel handling systems and costly combustion related engine damage.

- No solvents

- Quick and reliable determination.

- Full traceability with built-in database

Asphaltenes

SV10 Automated S Value – Intrinsic Stability of Asphaltenes

ASTM D7157 ISO PAS 23263 CIMAC guidelines

The SV10 has 3 independent test positions and fully automated operation including dilution, titration and cleaning meaning the operator has no contact with solvents.

The instrument comes pre-programmed for all typical sample types described in ASTM D7157, and the versatile software also allows fully customised tests.

"AD Systems offers cutting-edge automation for fuel and lubricant testing,

enhancing accuracy, efficiency, and productivity in laboratories."

Product FAQ's

It can analyse a broad spectrum of elements, from sodium (Na) to uranium (U).

Yes, it’s designed to accurately analyse solids, liquids, powders, and thin films.

With its touchscreen interface and automated features, it’s incredibly user-friendly, even for those new to XRF analysis.

Absolutely, it’s ideal for quality control applications across various industries due to its precision and versatility.

It offers high precision and flexibility in elemental analysis at a more economical price point compared to other systems, without compromising on quality or performance.

The NEX-QC+ is the ideal tool for measuring Silicon Si coating on paper. It will outperform all its rivals in the field as I has superior data evaluation capabilities.

Yes the NEX-QC is the ideal solution for testing silicone coat weight thickness on all types of materials such as paper and food packaging.

Applications

Application Note 1

Application Note 2

Application Note 3

Contact Us Today

We take great pleasure in assisting you and ensuring you get a prompt response to your questions

Live chat opening hours Mon – Fri 9:15 to 16:30 (UK Time)