Home » Products » Process Safety Solutions » VSP2 Adiabatic Calorimeter

VSP2 Adiabatic Calorimeter

VSP2 Adiabatic Calorimeter: Advanced Safety Evaluation revolutionises chemical safety with precise hazard analysis and emergency relief design insights.

Product Overview

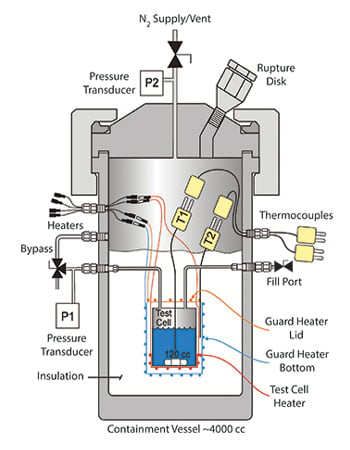

The Vent Sizing Package 2 (VSP2) Adiabatic Calorimeter is a state-of-the-art thermal hazard evaluation equipment designed for chemical process hazard characterisation.

It embodies the principles of DIERS technology safety data acquisition, providing essential insights into low Phi-factor calorimetry. This instrument is indispensable for professionals aiming to conduct a comprehensive runaway reaction analysis, ensuring the safe design of emergency relief systems.

By facilitating accurate adiabatic temperature rise detection and pressure rise rate measurement, the VSP2 plays a critical role in safeguarding chemical processes, making it an invaluable asset in the realm of process safety assessment tools.

Features & Benefits

Precision in Safety Data Acquisition

Comprehensive Hazard Characterisation

Essential data for Safety Analysis

Key applications

- DIERS Technology Integration: Employs cutting-edge DIERS methodology for precise safety parameters determination.

- Adiabatic Temperature Rise Detection: Guarantees accurate thermal hazard assessments by monitoring temperature fluctuations.

- Pressure Rise Rate Measurement: Offers real-time data on pressure changes, crucial for emergency relief sizing.

- Chemical Process Hazard Characterization: Enables comprehensive analysis of chemical reaction hazards.

- Low Phi-Factor Calorimetry: Ensures high accuracy in thermal process safety analysis.

VSP2 Adiabatic Calorimeter Product Videos

About the VSP2 Adiabatic Calorimeter

The VSP2 Adiabatic Calorimeter is a great tool for thermal process safety analysis.

At its core, this device addresses the critical need for robust chemical process hazard characterisation, a fundamental aspect of modern chemical engineering that safeguards against catastrophic industrial accidents.

The design of the VSP2 is rooted in the recognition of the intricate dynamics of chemical reactions, which can often behave unpredictably under certain conditions, leading to runaway reactions that pose severe risks to both personnel and infrastructure.

The VSP2 integrates with DIERS technology, renowned for its precision in safety parameters determination. This integration allows for the meticulous evaluation of chemical reactions, facilitating an analysis that identifies potential hazards before they escalate.

Moreover, the device’s capability for adiabatic temperature rise detection and pressure rise rate measurement is instrumental in the design of an effective emergency relief system.

One of the standout features of the VSP2 is its emphasis on low Phi-factor calorimetry.

This approach minimizes the heat loss effects commonly associated with traditional calorimetry methods, yielding more accurate data that is crucial for reliable chemical process hazard characterisation.

Such precision is invaluable for industries where the margin for error is negligible, offering a level of assurance that conventional methods cannot match.

The VSP2 is not merely a tool but a comprehensive solution that addresses the multifaceted challenges of thermal process safety analysis.

By providing detailed insights into the behaviour of chemical reactions, it enables engineers and safety professionals to design more effective emergency relief systems, optimise process safety management tools, and ultimately, contribute to a safer industrial environment.

This device stands as a testament to the advancements in chemical safety technology, offering a blend of precision, reliability, and innovation that is unparalleled in the field.

"The Vent Sizing Package 2 (VSP2) by Fauske offers critical safety insights,

enabling precise assessment of chemical reaction hazards for effective process safety management."

Product FAQ's

The VSP2 Adiabatic Calorimeter is advanced equipment used for thermal hazard evaluation and chemical process hazard characterisation, incorporating DIERS technology for precise safety analysis.

By providing accurate data on adiabatic temperature rise and pressure change rates, the VSP2 aids in designing emergency relief systems that are both effective and compliant with safety standards.

Low Phi-factor calorimetry reduces heat loss effects, ensuring high accuracy in thermal process safety analysis, crucial for reliable chemical reaction hazard assessments.

Yes, the VSP2 provides essential process scale-up safety data, helping to identify potential hazards and design mitigations before industrial scale-up.

By offering comprehensive data on chemical reaction hazards and safety parameters, the VSP2 is a vital tool in developing and implementing robust process safety management strategies.

Applications

Application Note 2

Application Note 3

Contact Us Today

We take great pleasure in assisting you and ensuring you get a prompt response to your questions

Live chat opening hours Mon – Fri 9:15 to 16:30 (UK Time)