Home » Products » Petroleum Testing » Automatic Microscale Closed Cup Flash » Automatic Microscale Continuously Closed Cup Flash Point Analyzer

Automatic Microscale Continuously Closed Cup Flash Point Analyser

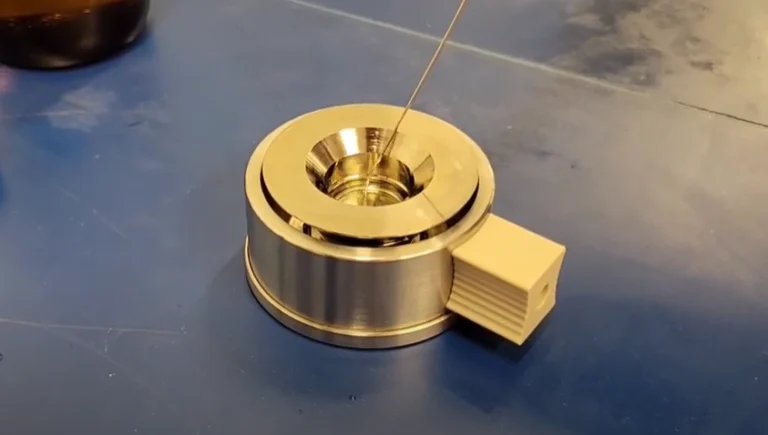

The Automatic Microscale Continuously Closed Cup Analyser provides quick and easy flash point determination of small volumes of many volatile liquids. Conforms to ASTM D6450 and D7094.

Product Overview

The Koehler K24880 Microscale Continuously Closed Cup Flash Point Analyser is a top-of-the-line solution for determining the flash point of a wide range of liquids such as:

fuel oils, lubricant oils, solvents, petroleum products, transformer oil, turbine oil, paint, perfumes, wood preservative oil, aromatic oil, animal and vegetable oil, pesticide emulsifier, high viscosity materials, plasticisers and other substances.

Conforms to the specifications of:

ASTM D6450 and D7094:

ASTM D6450 is for flash point determination of fuel and lube oils, solvents and other liquids by continuously closed cup. Requiring 1 mL of sample and utilising a closed but unsealed cup with air injected into the test chamber, this method is suitable for samples with a flash point between 10 °C to 250 °C.

ASTM D7094 is for flash point determination of fuels including diesel/biodiesel blends, lube oils, solvents, and other liquids using continuously closed cup tester. Requiring 2 mL of sample with a cup size of 7 mL and a heating rate of 2.5 °C per minute, this test uses a closed but unsealed cup with air injected into the test chamber, this method is suitable for testing samples with a flash point between 35 °C to 225 °C.

Additionally, the Pensky-Martens closed cup method and rapid equilibrium closed cup method are feasible on this instrument by changing parameters. The correlation between these methods is very high.

Excellent Correlation to: ASTM D56, D93, D3278, D3828; IP 170; EN ISO 6379 / 3680; ISO 2719; SH/T 0768, SH/T 3077.1, SH/T 3077.2, DL/T 1354, GB/T 261, GB/T 21615, GB/T 5208, GB/T 21790

Features & Benefits

K24880 Model

Advanced Precision

ASTM Standards

Industry Compliance

Flash Point Range

-10 °C to 400 °C

Key applications

- 7-inch Integrated Colour Touch Screen

- Built-in standard test methods which can be correlated to other closed cup methods

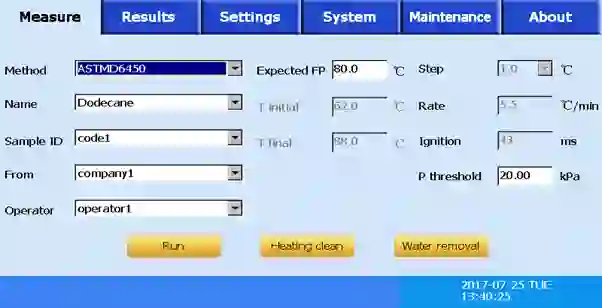

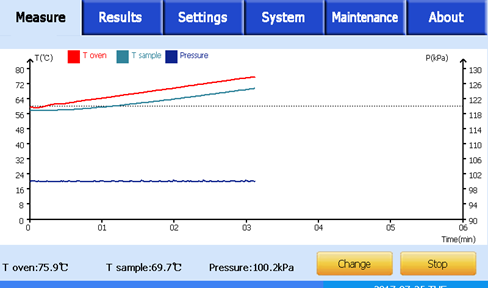

- Real-time display of temperature and pressure curves

- Temperature Range: -30 °C to 405°C (-22 °F to 788 °F); below 0 °C an external cryogenic recirculatory is required, which can be provided by SciMed.

- Heating Rate: 5 °C/min ±0.3 °C/min or 5.5 °C/min ± 0.5 °C/min; this can be customised in the range of 0.5 to 12 C/min

- Temperature Accuracy: ± 1 °C

- Pressure Range: 0 kPa to 200 kPa

- Sample Volume: 1 mL or 2 mL

- Ignition method: High voltage electric ignition

- Stirring Rate: Customisable from 50 RPM to 300 RPM

- Interfaces:, USB, Ethernet,RS232

K24880 Automatic Microscale Continuously Closed Cup Flash Point Analyser

About the Automatic Microscale Continuously Closed Cup Flash Point Analyser

There are two modes of operation for the K24880 Automatic Microscale Continuously Closed Cup Flash Point Analyser: manual sampling and automatic sampling. When set to “Auto off” the sample is put into the test chamber after the temperature of the oven is at the initial temperature. When set to “Auto on” the sample is put into the test chamber at the beginning, and once the temperature is at the initial temperature the test will run automatically.

Select the “Method” dropdown menu and choose the test method. Each method has its own interface but if required you can customise your own methods.

Input the sample name, sample number, sample source, and personnel information. The last 10 values which were typed in will be saved in the drop-down box.

Set the expected flash point temperature if known. The instrument calculates the initial temperature and end temperature automatically based on the expected flash point.

- The initial temperature for the continuously closed cup method and advanced continuously closed cup method is 18 °C lower than the expected flash point, and the end temperature is 26 °C higher than the initial temperature.

- The initial temperature of Pensky-Martens closed cup method is 23 °C lower than the expected flash point, and the end temperature is 28 °C higher than the initial temperature;

When the initial temperature is below 0 °C, it’s necessary to set the cooling mode. The sample refrigerating mode can be set to instrument refrigerating or external refrigerating.

After the selection of “Method”, corresponding parameters such as Rate (heating rate), Step (ignition frequency), Ignition (ignition interval), P threshold (pressure threshold) and equilibrium time are displayed. The equilibrium time is not usually displayed except for the rapid equilibrium closed cup method.

The default pressure threshold is 20 kPa and in most conditions there is no need to change this.

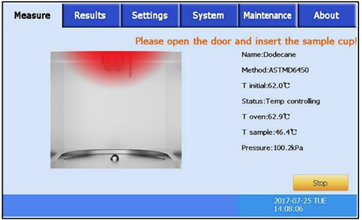

Press the “run” button to begin the test, and the instrument will begin to heat. When the temperature of the oven reaches the initial temperature, the instrument will bring up a popup message, shown below, which says to insert the sample cup.

If you choose the automatic sampling mode, it will raise the sample cup automatically and run the test.

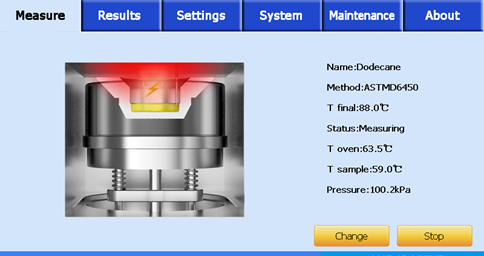

The instrument raises the sample cup to run the test automatically after closing the test chamber. The present measurement method, sample name, temperature and pressure are displayed on the interface. Press the “Change” button to switch between the parameters interface and the curve interface.

If you choose the automatic sampling mode, it will raise the sample cup automatically and run the test.

The instrument raises the sample cup to run the test automatically after closing the test chamber. The present measurement method, sample name, temperature and pressure are displayed on the interface. Press the “Change” button to switch between the parameters interface and the curve interface.

Parameter Interface

Curve Interface

Flash point is detected by an increase in pressure as can be seen on the video. The results of the flash point measurement are displayed automatically.

When the measurement is done, the instrument begins to cool down to a safe temperature.

The instrument can store up to 5000 results.

Unknown Flashpoints

When the flash point of the substance is unknown, the scanning method can be used which has a higher heating rate and wider control temperature ranges. The default parameters (e.g. rate and ignition, etc.) of the scanning method are the same parameters of ASTM D7094. The parameters can be changed as required.

"The Koehler K24880 is an advanced, automatic flash point

analyser for fuels and lubricants, offering precise,

safe testing with minimal sample requirements."

Product FAQ's

No, the instrument has an electronic ignition

The instrument monitors the pressure. At the flashpoint there is a sudden increase in pressure – this can clearly be seen on the video.

Although the instrument only requires 1 or 2mls of sample, according to ASTM D4057 or GB/T 4756, take at least 50mL of sample and place it in a clean container which has been sealed for low temperature preservation. This is to preserve the volatiles, which if allowed to escape, will affect the flash point results and could give and erroneously high flash point.

The sample should be stored in a suitable container. A container such as a plastic bottle with high gas permeability is not suitable to store the sample as volatile materials can spread through the walls of the container. Appropriate measures should be taken to avoid the loss of volatile materials which can affect the results. You should not open the container, unless necessary. Only when the temperature of the sample is 18 °C lower than the expected flash point is it appropriate to pour the sample.

Yes the instrument automatically detects the flash point and displays the result.

Applications

Application Note 1

Application Note 2

Application Note 3

Contact Us Today

We take great pleasure in assisting you and ensuring you get a prompt response to your questions

Live chat opening hours Mon – Fri 9:15 to 16:30 (UK Time)