Home » Products » Petroleum Testing » SP20

SP20 AD Systems Smoke Point Tester

The SP20 AD Systems Smoke Point Tester provides automated, ASTM D1322-compliant smoke point analysis for aviation turbine fuels and kerosene.

Product Overview

The SP20 AD Systems Smoke Point Tester is an advanced, fully automated fuel combustion property analysis tool designed to determine the smoke point of kerosene and aviation turbine fuels.

This next-generation aviation fuel testing device provides accurate, reliable results while significantly reducing operator workload. With compliance to ASTM D1322, D1655, and IP 598, the SP20 eliminates the subjectivity associated with manual smoke point measurement.

Using digital imaging smoke point analysis and an innovative atmospheric compensation system, the SP20 ensures precision testing for aviation fuel quality control. This compact, automated smoke point tester is ideal for research laboratories, fuel testing facilities, and regulatory agencies.

Features & Benefits

Automated Testing: Reduces manual labour.

ASTM-Compliant Analysis: Meets D1322 and IP 598 standards.

Digital Flame Imaging: Ensures precise measurements.

Fast and Reliable: Less than 10 minutes per test.

Key applications

- SP20 AD Systems Smoke Point Tester: Fully automated, high-precision smoke point analyser.

- Automated Smoke Point Testing for Aviation Fuels: Provides reliable results for jet fuel quality control.

- ASTM D1322 Smoke Point Analysis: Meets international industry standards for fuel testing.

- Smoke Point Measurement for Kerosene and Jet Fuel: Determines fuel combustion properties.

- High-Precision Smoke Point Analyser: Delivers repeatable, accurate measurements.

- Automated Fuel Smoke Point Testing Equipment: Reduces labour and increases efficiency.

- Aviation Turbine Fuel Smoke Point Determination: Crucial for assessing combustion characteristics.

- Reliable Jet Fuel Quality Control Instrument: Ensures compliance with industry regulations.

- Digital Imaging Smoke Point Analysis: Eliminates human subjectivity in flame height determination.

- Smoke Point Tester with Atmospheric Compensation: Adjusts for variations in temperature, pressure, and humidity.

SP20 AD Systems Smoke Point Tester Product Video

About the SP20 AD Systems Smoke Point Tester

The SP20 AD SystemsSmoke Point Tester is a game-changer in aviation fuel testing, providing an automated solution for determining the smoke point of kerosene and jet fuel. In aviation, fuel quality is critical for ensuring efficiency, engine longevity, and safety. The smoke point test is essential for measuring the combustion characteristics of fuels, as higher smoke points indicate better combustion performance with lower particulate emissions. Traditional smoke point measurement methods are highly manual and require skilled technicians to visually assess the flame height, making them time-consuming and prone to human error.

The SP20 revolutionises this process with its fully automated smoke point measurement system. It eliminates subjectivity by using digital imaging technology to determine the flame height with unmatched precision. The instrument is compliant with ASTM D1322, D1655, IP 598, and DEF STAN 91-091, ensuring that fuel quality assessment aligns with global industry standards.

One of the most significant advantages of the SP20 is its embedded temperature, humidity, and pressure sensors, which allow for automatic atmospheric compensation.

This innovative feature corrects for environmental variations, ensuring consistent and repeatable results, regardless of lab conditions. With its high-precision smoke point analyser capabilities, laboratories and fuel quality control facilities can reduce variability in test results, improving reliability and compliance.

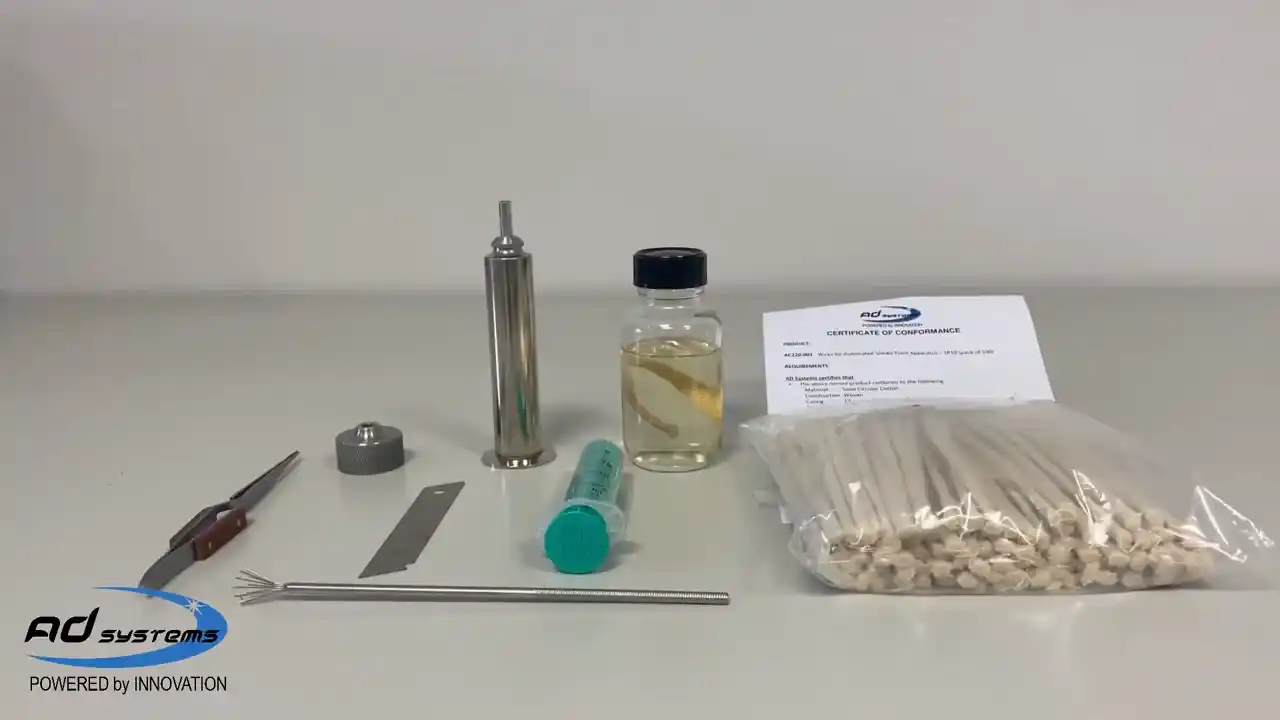

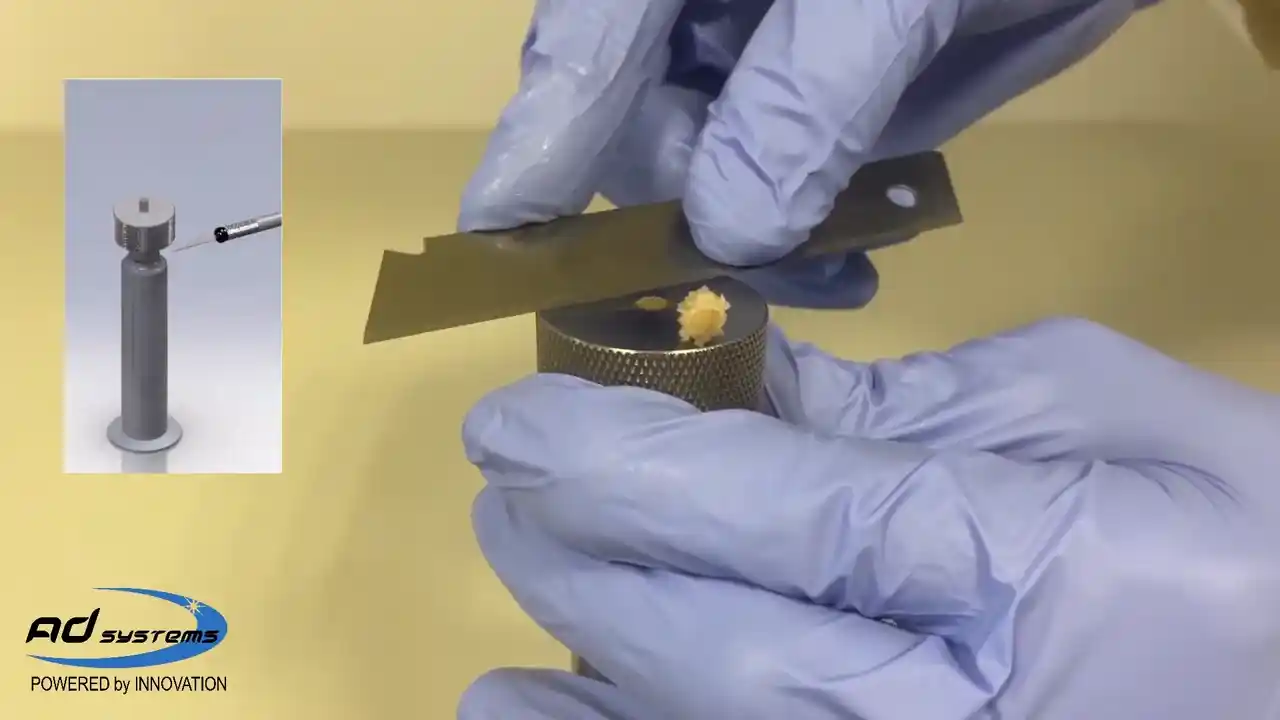

The SP20 also dramatically reduces operator workload. In traditional methods, calibration involves preparing multiple fuel mixtures and manually adjusting the flame to observe the smoke point. This process can take hours and requires expert knowledge. With the SP20, the operator simply places the sample, inputs test parameters, and initiates the analysis. The system automatically stabilises the flame, captures digital images, calculates the average flame height, and records the final smoke point measurement. The results are stored in an internal database and can be printed, exported to LIMS, or transferred via USB.

Designed as an efficient dry point analysis for research labs and fuel quality testing facilities, the SP20 offers a compact, user-friendly interface with an 8-inch touchscreen. Its automated functionality enhances efficiency and precision, making it an indispensable tool for aviation fuel testing, petrochemical research, and regulatory compliance.

"The SP20 is an automated smoke point tester that uses

digital imaging to remove subjectivity from jet fuel analysis."

Product FAQ's

The SP20 is a fully automated, high-precision smoke point analyser that eliminates manual subjectivity using digital imaging technology.

It provides ASTM D1322-compliant smoke point analysis with automated flame height detection, reducing human error and improving accuracy.

The SP20 is designed for smoke point measurement for kerosene and jet fuel, ensuring aviation fuel quality control.

Yes, the SP20 is designed for user-friendly operation, featuring an intuitive touchscreen interface and automated test sequences.

The SP20’s embedded sensors adjust for temperature, pressure, and humidity variations, ensuring consistent and repeatable results.

Applications

Application Note 1

Application Note 2

Application Note 3

Contact Us Today

We take great pleasure in assisting you and ensuring you get a prompt response to your questions

Live chat opening hours Mon – Fri 9:15 to 16:30 (UK Time)